LTC4012IUF-1#TRPBF Linear Technology, LTC4012IUF-1#TRPBF Datasheet - Page 22

LTC4012IUF-1#TRPBF

Manufacturer Part Number

LTC4012IUF-1#TRPBF

Description

IC CTLR BATT CHARGER CC/CV 20QFN

Manufacturer

Linear Technology

Datasheet

1.LTC4012CUFPBF.pdf

(28 pages)

Specifications of LTC4012IUF-1#TRPBF

Function

Charge Management

Battery Type

Multi-Chemistry

Voltage - Supply

6 V ~ 28 V

Operating Temperature

-40°C ~ 125°C

Mounting Type

Surface Mount

Package / Case

20-WFQFN Exposed Pad

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

applications inForMation

LTC4012/

LTC4012-1/LTC4012-2

R

ues of R

programmed current accuracy. Use these equations and

guidelines, as represented in Table 6, to help select the cor-

rect inductor value. This table was developed for C-grade

parts to maintain maximum ∆I

550kHz and V

assuming that inductor value could also vary by 25% at

I

0.4 • I

batteries over the wider I-grade temperature range. In that

case, a good starting point can be found by multiplying

the inductor values shown in Table 6 by a factor of 1.6 and

rounding up to the nearest standard value.

Table 6. Minimum Typical Inductor Values

To guarantee that a chosen inductor is optimized in any

given application, use the design equations provided and

perform bench evaluation in the target application, par-

ticularly at duty cycles below 20% or above 80% where

PWM frequency can be much less than the nominal value

of 550kHz.

MAX

10V to 20V

10V to 20V

10V to 20V

10V to 20V

IN

<10V

>20V

<10V

>20V

<10V

>20V

<10V

>20V

V

should not be less than 2.37k or more than 6.04k. Val-

. For I-grade parts, reduce maximum ∆I

CLP

MAX

IN

, but only if the IC will actually be used to charge

greater than 3.01k may cause some reduction in

≥5.1µH

≥3.4µH

≥6.8µH

≥9.5µH

≥2.5µH

≥5.1µH

≥7.1µH

BAT

≥10µH

≥20µH

≥28µH

≥10µH

≥14µH

(Typ)

L1

= 0.5 • V

I

MAX

1A

1A

1A

2A

2A

2A

3A

3A

3A

4A

4A

4A

CLP

(the point of maximum ∆I

L

100mΩ

100mΩ

100mΩ

R

near 0.6 • I

50mΩ

50mΩ

50mΩ

33mΩ

33mΩ

33mΩ

25mΩ

25mΩ

25mΩ

SENSE

3.01k

3.01k

3.01k

3.01k

3.01k

3.01k

3.01k

3.01k

3.01k

3.01k

3.01k

3.01k

MAX

R

IN

L

with f

to less than

R

26.7k

26.7k

26.7k

26.7k

26.7k

26.7k

26.7k

26.7k

26.7k

26.7k

26.7k

26.7k

PWM

PROG

L

at

),

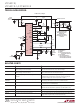

TGATE BOOST Supply

Use the external components shown in Figure 11 to de-

velop a bootstrapped BOOST supply for the TGATE FET

driver. A good set of equations governing selection of the

two capacitors is:

where Q

with V

then given by:

To improve efficiency by increasing V

top FET, substitute a Schottky diode with low reverse

leakage for D1.

PWM jitter has been observed in some designs operating

at higher V

affect DC charge current accuracy. A series resistor with a

value of 5Ω to 20Ω can be inserted between the cathode

of D1 and the BOOST pin to remove this jitter, if present.

A resistor case size of 0603 or larger is recommended to

lower ESL and achieve the best results.

I

C

D

1

= Q

=

GS

G

20

G

= 4.5V. The maximum average diode current is

4 5

is the rated gate charge of the top external NFET

IN

• 665kHz

.

•

LTC4012

/V

Q

V

INTV

BOOST

G

OUT

Figure 11. TGATE Boost Supply

,

SW

DD

C

ratios. This jitter does not substantially

2 20

20

17

18

=

4012 F11

•

C

D1

1N4148

C2

2µF

1

C1

0.1µF

L1

GS

applied to the

TO

R

SENSE

4012fa