LM2575HVS-15/NOPB National Semiconductor, LM2575HVS-15/NOPB Datasheet - Page 19

LM2575HVS-15/NOPB

Manufacturer Part Number

LM2575HVS-15/NOPB

Description

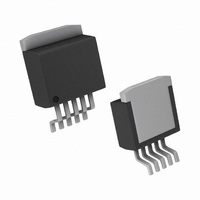

IC REG SIMPLE SWITCHER TO-263-5

Manufacturer

National Semiconductor

Series

SIMPLE SWITCHER®r

Type

Step-Down (Buck)r

Datasheet

1.LM2575S-5.0NOPB.pdf

(28 pages)

Specifications of LM2575HVS-15/NOPB

Internal Switch(s)

Yes

Synchronous Rectifier

No

Number Of Outputs

1

Voltage - Output

15V

Current - Output

1A

Frequency - Switching

52kHz

Voltage - Input

4 ~ 60 V

Operating Temperature

-40°C ~ 125°C

Mounting Type

Surface Mount

Package / Case

D²Pak, TO-263 (5 leads + tab)

Input Voltage

60V

Output Current

1A

Output Voltage

37V

No. Of Pins

5

Operating Temperature Range

-40°C To +125°C

Msl

MSL 3 - 168 Hours

Switching Frequency Max

52kHz

Termination Type

SMD

Rohs Compliant

Yes

Filter Terminals

SMD

Input Voltage Primary Max

60V

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Power - Output

-

Other names

*LM2575HVS-15

*LM2575HVS-15/NOPB

LM2575HVS-15

*LM2575HVS-15/NOPB

LM2575HVS-15

be used in parallel with aluminum electrolytics, with the tan-

talum making up 10% or 20% of the total capacitance.

The capacitor's ripple current rating at 52 kHz should be at

least 50% higher than the peak-to-peak inductor ripple cur-

rent.

CATCH DIODE

Buck regulators require a diode to provide a return path for

the inductor current when the switch is off. This diode should

be located close to the LM2575 using short leads and short

printed circuit traces.

Because of their fast switching speed and low forward voltage

drop, Schottky diodes provide the best efficiency, especially

in low output voltage switching regulators (less than 5V). Fast-

Recovery, High-Efficiency, or Ultra-Fast Recovery diodes are

also suitable, but some types with an abrupt turn-off charac-

teristic may cause instability and EMI problems. A fast-recov-

ery diode with soft recovery characteristics is a better choice.

Standard 60 Hz diodes (e.g., 1N4001 or 1N5400, etc.) are

also not suitable. See Figure 8 for Schottky and “soft” fast-

recovery diode selection guide.

OUTPUT VOLTAGE RIPPLE AND TRANSIENTS

The output voltage of a switching power supply will contain a

sawtooth ripple voltage at the switcher frequency, typically

about 1% of the output voltage, and may also contain short

voltage spikes at the peaks of the sawtooth waveform.

The output ripple voltage is due mainly to the inductor saw-

tooth ripple current multiplied by the ESR of the output ca-

pacitor. (See the inductor selection in the application hints.)

The voltage spikes are present because of the fast switching

action of the output switch, and the parasitic inductance of the

output filter capacitor. To minimize these voltage spikes, spe-

cial low inductance capacitors can be used, and their lead

lengths must be kept short. Wiring inductance, stray capaci-

tance, as well as the scope probe used to evaluate these

transients, all contribute to the amplitude of these spikes.

An additional small LC filter (20 μH & 100 μF) can be added

to the output (as shown in Figure 15) to further reduce the

amount of output ripple and transients. A 10 × reduction in

output ripple voltage and transients is possible with this filter.

FEEDBACK CONNECTION

The LM2575 (fixed voltage versions) feedback pin must be

wired to the output voltage point of the switching power sup-

ply. When using the adjustable version, physically locate both

output voltage programming resistors near the LM2575 to

avoid picking up unwanted noise. Avoid using resistors

greater than 100 kΩ because of the increased chance of noise

pickup.

ON /OFF INPUT

For normal operation, the ON /OFF pin should be grounded

or driven with a low-level TTL voltage (typically below 1.6V).

To put the regulator into standby mode, drive this pin with a

high-level TTL or CMOS signal. The ON /OFF pin can be

safely pulled up to +V

ON /OFF pin should not be left open.

GROUNDING

To maintain output voltage stability, the power ground con-

nections must be low-impedance (see Figure 2). For the TO-3

style package, the case is ground. For the 5-lead TO-220 style

package, both the tab and pin 3 are ground and either con-

nection may be used, as they are both part of the same copper

lead frame.

IN

without a resistor in series with it. The

19

With the N or M packages, all the pins labeled ground, power

ground, or signal ground should be soldered directly to wide

printed circuit board copper traces. This assures both low in-

ductance connections and good thermal properties.

HEAT SINK/THERMAL CONSIDERATIONS

In many cases, no heat sink is required to keep the LM2575

junction temperature within the allowed operating range. For

each application, to determine whether or not a heat sink will

be required, the following must be identified:

1.

2.

3.

4.

Total power dissipated by the LM2575 can be estimated as

follows:

where I

Characteristic Curves shown previously, V

minimum input voltage, V

and I

on and turn-off are negligible if a Schottky type catch diode is

used.

When no heat sink is used, the junction temperature rise can

be determined by the following:

To arrive at the actual operating junction temperature, add the

junction temperature rise to the maximum ambient tempera-

ture.

If the actual operating junction temperature is greater than the

selected safe operating junction temperature determined in

step 3, then a heat sink is required.

When using a heat sink, the junction temperature rise can be

determined by the following:

The operating junction temperature will be:

As above, if the actual operating junction temperature is

greater than the selected safe operating junction tempera-

ture, then a larger heat sink is required (one that has a lower

thermal resistance).

When using the LM2575 in the plastic DIP (N) or surface

mount (M) packages, several items about the thermal prop-

erties of the packages should be understood. The majority of

the heat is conducted out of the package through the leads,

with a minor portion through the plastic parts of the package.

Since the lead frame is solid copper, heat from the die is

readily conducted through the leads to the printed circuit

board copper, which is acting as a heat sink.

For best thermal performance, the ground pins and all the

unconnected pins should be soldered to generous amounts

of printed circuit board copper, such as a ground plane. Large

areas of copper provide the best transfer of heat to the sur-

rounding air. Copper on both sides of the board is also helpful

in getting the heat away from the package, even if there is no

direct copper contact between the two sides. Thermal resis-

Maximum ambient temperature (in the application).

Maximum regulator power dissipation (in application).

Maximum allowed junction temperature (150°C for the

LM1575 or 125°C for the LM2575). For a safe,

conservative design, a temperature approximately 15°C

cooler than the maximum temperature should be

selected.

LM2575 package thermal resistances θ

LOAD

Q

(quiescent current) and V

is the load current. The dynamic losses during turn-

P

ΔT

D

= (V

J

= (P

IN

) (I

D

) (θ

ΔT

Q

T

T

) + (V

J

J

JC

J

O

= ΔT

= T

= (P

+ θ

is the regulated output voltage,

O

A

D

interface

/V

J

+ ΔT

) (θ

+ T

IN

) (I

JA

A

SAT

J

)

LOAD

+ θ

can be found in the

Heat sink

) (V

IN

JA

SAT

is the applied

and θ

)

www.national.com

)

JC

.