HLMP-D401 Avago Technologies US Inc., HLMP-D401 Datasheet - Page 11

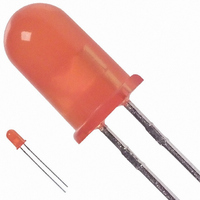

HLMP-D401

Manufacturer Part Number

HLMP-D401

Description

LED 5MM 600NM ORANGE DIFF

Manufacturer

Avago Technologies US Inc.

Type

Uni-Colorr

Specifications of HLMP-D401

Viewing Angle

60°

Package / Case

Radial - 2 Lead

Color

Orange

Millicandela Rating

5.4mcd

Current - Test

10mA

Wavelength - Dominant

602nm

Wavelength - Peak

600nm

Voltage - Forward (vf) Typ

1.9V

Lens Type

Diffused, Orange Tinted

Lens Style/size

Round, 5mm, T-1 3/4

Height

8.81mm

Mounting Type

Through Hole

Resistance Tolerance

602nm

Led Size

T-1 3/4

Illumination Color

Orange

Lens Color/style

Tinted Diffused

Operating Voltage

1.9 V

Wavelength

602 nm

Luminous Intensity

5.4 mcd

Operating Current

10 mA

Lens Dimensions

5 mm

Lens Shape

Dome

Maximum Operating Temperature

+ 100 C

Minimum Operating Temperature

- 40 C

Mounting Style

Through Hole

Color, Emitted

Orange

Current, Forward

90 mA

Diameter

3 mm

Finish, Lens

Diffused

Package Type

3 mm (T-1)

Temperature, Operating, Maximum

+100 °C

Temperature, Operating, Minimum

-55 °C

Temperature, Soldering

+260 °C

Voltage, Forward

2 V

Voltage, Reverse

5 V

Wavelength, Peak

583 nm

Emitting Color

Orange

Test Current (it)

10mA

Forward Current

25mA

Dominant Wave Length

602nm

Forward Voltage

2.4V

Product Length (mm)

6.1mm

Product Height (mm)

9.19mm

Product Depth (mm)

6.1mm

Mounting

Through Hole

Peak Wavelength

600nm

Shape Type

Circular

Chip Material

GaP

Main Category

Standard LED

Number Of Elements

1

Pin Count

2

Operating Temperature Classification

Industrial

Operating Temp Range

-40C to 100C

Reverse Voltage

5V

Power Dissipation

85mW

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Luminous Flux @ Current - Test

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

516-1330

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

HLMP-D401

Manufacturer:

AVAGO

Quantity:

50 000

Company:

Part Number:

HLMP-D401-EF0FH

Manufacturer:

AVAGO

Quantity:

40 000

Company:

Part Number:

HLMP-D401-EF0FH

Manufacturer:

AVAGO

Quantity:

50 000

Company:

Part Number:

HLMP-D401-FI0UT

Manufacturer:

AVAGO

Quantity:

40 000

Precautions

Lead Forming

• The leads of an LED lamp may be preformed or cut to

• If lead forming is required before soldering, care must be

• It is recommended that tooling made to precisely form

Soldering Conditions

• Care must be taken during PCB assembly and soldering

• The closest LED is allowed to solder on board is 1.59

• Recommended soldering conditions:

For product information and a complete list of distributors, please go to our website:

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2008 Avago Technologies. All rights reserved. Obsoletes 5989-4258EN

AV02-1558EN - October 13, 2008

length prior to insertion and soldering into PC board.

taken to avoid any excessive mechanical stress induced

to LED package. Otherwise, cut the leads of LED to length

after soldering process at room temperature. The solder

joint formed will absorb the mechanical stress of the

lead cutting from traveling to the LED chip die attach

and wirebond.

and cut the leads to length rather than rely upon hand

operation.

process to prevent damage to LED component.

mm below the body (encapsulant epoxy) for those parts

without standoff.

Pre-heat Temperature 105 °C Max.

Pre-heat Time

Peak Temperature

Dwell Time

Figure 17. Recommended wave soldering profile

250

200

150

100

50

30

0

10

FLUXING

TURBULENT WAVE

PREHEAT

20

30

TIME – SECONDS

40

Wave Soldering

30 sec Max.

250 °C Max.

3 sec Max.

50

60

70

LAMINAR WAVE

HOT AIR KNIFE

80

Manual Solder

Dipping

–

–

260 °C Max.

5 sec Max.

90

100

CONVEYOR SPEED = 1.83 M/MIN (6 FT/MIN)

PREHEAT SETTING = 150°C (100°C PCB)

SOLDER WAVE TEMPERATURE = 245°C

AIR KNIFE AIR TEMPERATURE = 390°C

AIR KNIFE DISTANCE = 1.91 mm (0.25 IN.)

AIR KNIFE ANGLE = 40°

SOLDER: SN63; FLUX: RMA

NOTE: ALLOW FOR BOARDS TO BE

SUFFICIENTLY COOLED BEFORE EXERTING

MECHANICAL FORCE.

BOTTOM SIDE

OF PC BOARD

TOP SIDE OF

PC BOARD

www.avagotech.com

• Wave soldering parameter must be set and maintained

• If necessary, use fixture to hold the LED component

• Proper handling is imperative to avoid excessive thermal

• Special attention must be given to board fabrication,

• Recommended PC board plated through hole sizes for

according to recommended temperature and dwell time

in the solder wave. Customer is advised to periodically

check on the soldering profile to ensure the soldering

profile used is always conforming to recommended

soldering condition.

in proper orientation with respect to the PCB during

soldering process.

stresses to LED components when heated. Therefore,

the soldered PCB must be allowed to cool to room

temperature, 25°C, before handling.

solder masking, surface plating and lead holes size and

component orientation to assure solderability.

LED component leads:

Note:

soldering LED components.

LED Component

Lead Size

0.457 x 0.457 mm

(0.018 x 0.018 inch)

0.508 x 0.508 mm

(0.020 x 0.020 inch)

Refer to application note AN1027 for more information on

Diagonal

0.646 mm

(0.025 inch)

0.718 mm

(0.028 inch)

Plated Through

Hole Diameter

0.976 to 1.078 mm

(0.038 to 0.042 inch)

1.049 to 1.150 mm

(0.041 to 0.045 inch)