TL12W03-D(T30) Toshiba, TL12W03-D(T30) Datasheet - Page 5

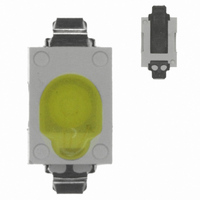

TL12W03-D(T30)

Manufacturer Part Number

TL12W03-D(T30)

Description

LED WHITE 6500K 10.5X5MM SMD

Manufacturer

Toshiba

Datasheet

1.TL12W03-DT30.pdf

(10 pages)

Specifications of TL12W03-D(T30)

Color

White, Cool

Current - Test

350mA

Luminous Flux @ Current - Test

90lm

Current - Max

500mA

Lumens @ Current - Max

99lm

Lumens/watt @ Current - Test

78lm/W

Voltage - Forward (vf) Typ

3.3V

Wavelength

6500K

Lens Style/size

Rectangle, 7mm x 5mm

Mounting Type

Surface Mount

Package / Case

0.41" L x 0.2" W x 0.08" H (10.5mm x 5mm x 2.1mm)

For Use With

876-1003 - LM3406 LED DRIVER EVAL BOARD

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Viewing Angle

-

Other names

TL12W03-DT30TR

Packaging

This LED device is packed in an aluminum envelope with a silica gel and a moisture indicator to avoid moisture

absorption. The optical characteristics of the devices may be affected by exposure to moisture in the air before

soldering and they should therefore be stored under the following conditions:

Mounting Method

•

•

•

•

•

•

1. This moisture proof bag may be stored unopened within 12 months at the following conditions.

2. After opening the moisture proof bag, the device should be assembled within 168 hours in an environment of

3. If upon opening, the moisture indicator card shows humidity 30% or above (Color of indication changes to

4. Repeated baking can cause the peeling strength of the taping to change, then leads to trouble in mounting.

5. If the packing material of laminate would be broken, the hermeticity would deteriorate. Therefore, do not

Soldering

Reflow soldering (example)

The product is evaluated using above reflow soldering conditions. No additional test is performed exceed the

condition (i.e. the condition more than (*)MAX values) as a evaluation. Please perform reflow soldering under

the above conditions.

Please perform the first reflow soldering with reference to the above temperature profile and within 168 h of

opening the package.

Second reflow soldering

In case of second reflow soldering should be performed within 168 h of the first reflow under the above

conditions.

Storage conditions before the second reflow soldering: 30°C, 60% RH (max)

When any soldering corrections are made manually,a hot-plate should be used .

(only once at each soldering point)

Do not perform wave soldering.

Temperature of a hot plate: 150°C

Soldering iron:

Temperature:

Time:

Temperature: 5°C to 30°C

Humidity: 90% (max)

5°C to 30°C/60% RH or below.

pink) or the expiration date has passed, the devices should be baked in taping with reel.

After baking, use the baked devices within 72 hours, but perform baking only once.

Baking conditions: 60±5°C, for 24 to 48 hours.

Expiration date: 12 months from sealing date, which is imprinted on the label affixed.

throw or drop the packed devices.

Temperature profile for Pb soldering (example)

4°C/s max

(*)

240°C max

140 to 160°C

60 to 120 s

Time (s)

max

(*)

(*)

25 W

350°C or less

within 3 s

max

10 s max

4°C/s max

(*)

(*)

(*)

5

Temperature profile for Pb-free soldering (example)

4°C/s max

150 to 180°C

max

260°C max

(*)

4°C/s max

(*)

60 to 120 s

230°C

Time (s)

(*)

(*)

max

30 to 50 s max

5 s max

TL12W03-D(T30)

(*)

(*)

(*)

2009-10-06