PV37P502A01B00 Murata Electronics North America, PV37P502A01B00 Datasheet - Page 22

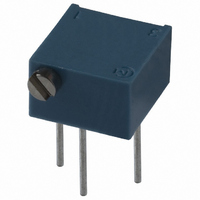

PV37P502A01B00

Manufacturer Part Number

PV37P502A01B00

Description

POT 5K OHM TRIM CERM 12TRN SIDE

Manufacturer

Murata Electronics North America

Series

PV37r

Datasheet

1.PV36W102C01B00.pdf

(22 pages)

Specifications of PV37P502A01B00

Resistance (ohms)

5K

Power (watts)

0.25W, 1/4W

Taper

Linear

Tolerance

±10%

Temperature Coefficient

±150ppm/°C

Number Of Turns

12

Adjustment Type

Side Adjustment

Mounting Type

Through Hole

Resistive Material

Cermet

Package / Case

Square - 0.264" L x 0.252" W x 0.157" H (6.70mm x 6.40mm x 4.00mm)

Resistance In Ohms

5.00K

Lead Free Status / RoHS Status

Lead free / RoHS non-compliant

Other names

490-2365

!Note

!Note

No.

13

14

Specifications and Test Methods

Continued from the preceding page.

Low Temperature Operation

(Only for PVF2 and

PVM4A---D01)

Rotational Life

• Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this PDF catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, you are requested to approve our product specifications or to transact the approval sheet for product specifications before ordering.

Item

SMD Sealed Type/Lead Sealed Type Specifications and Test Methods

The trimmer potentiometer should be placed in a chamber at a temperature of -25±3°C (-55±3°C for PVM4A---

D01 series) 48±4 hours without loading. The trimmer potentiometer should be removed from the chamber, and main-

tained at a temperature of 25±5°C for 1-2 hours

1)PV-- series

Full rated continuous working voltage not exceeding the maximum rated voltage should be applied with the circuit

shown in the figure. The adjustment rotor (screw) should be continuously cycled through not less than 90% of effec-

tive-electrical rotational angle (number of turns), at the rate of 1 cycle for 5 seconds minimum to 2.5 minutes maxi-

mum for total of 200 cycles.

2) PVG3, PVG5 series

The adjustment rotor (screw) should be continuously cycled though not less than 90% of effective-electrical rotation-

al angle (number of turns), at the rate of 1 cycle for 5 seconds minimum to 2.5 minutes maximum for a total of 50

(100 for PVG5) cycles, without loading.

3) PVF2, PVM4A---D01 series

The wiper should be rotated over 90% of the effective rotational angle without loading at a speed of 10 cycles per

minute, for 100 cycles continuously.

End Terminal

Resistor 1

End Terminal

Figure 4

DC supply

End Terminal

Resistor 2 End Terminal

Test Methods

R50E13.pdf 04.6.11

81

9