26231941 Crouzet USA, 26231941 Datasheet - Page 20

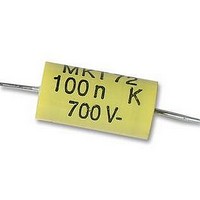

26231941

Manufacturer Part Number

26231941

Description

CAPACITOR, MOTOR MEDIUM TORQUE CAPACITOR, MOTOR MEDIUM TORQUE

Manufacturer

Crouzet USA

Datasheet

1.26231909.pdf

(196 pages)

Specifications of 26231941

Capacitance

0.1UF

Voltage Rating, Dc

700V

Capacitor Dielectric Type

POLYPROPYLENE

Tolerance,

10%

Tolerance, -

10%

Temp, Op. Max

85(DEGREE C)

Temp, Op. Min

0(DEGREE

- Current page: 20 of 196

- Download datasheet (6Mb)

1

20

➜ Temperature rise

The temperature rise of a motor is due to the difference between the

absorbed power and the output power of the motor. This difference is the

power loss.

Temperature rise is also related to the fact that power loss, in the form of

heat from the motor, is not rapidly absorbed by the ambient air (thermal

resistance). The thermal resistance of the motor can be greatly reduced

by ventilation.

Important

The nominal operating characteristics correspond to the voltage-

torque-speed characteristics required for continuous operation at

an ambient temperature of 20° C. Only intermittent duty is possible

outside these operating conditions : without exception, all checks

concerning extreme operating conditions must be performed in

the actual customer application conditions in order to ensure safe

operation.

D.C. motors are constructed to operate continuously within a range of

speeds near their no-load speed. This range of speeds is generally too

high for most applications. In order to reduce this speed, a full range of

geared motors is available, each with a series of gear ratios to suit most

speed requirements.

The complete range is suitable for a wide variety of applications.

➜ Gearbox characteristics

Our gearboxes have been designed for optimum performance and for

maximum life under normal operating conditions.

Their main characteristic is the capacity to withstand maximum design

torque with continuous duty.

The range of gearboxes shown in this catalogue can operate with

maximum torque of 0.5 to 6 N.m for long time periods. All values

previously stated are for standard products in normal operating

conditions, as specified.

In certain cases, these values may be increased if a shorter life is

required.

Please consult our Sales Office for further information.

Every gearbox has a torque limit, which is

If this torque is applied to the gearbox, it will cause severe damage.

➜ Gearbox construction

Motor and gearbox combinations

D.C. Motor

Gearbox case

the breaking torque

Motor shaft

Gearwheels

Output shaft

Bearing

➜ Selection of a geared motor

A geared motor is selected according to the required usable power

output.

A geared motor must have usable power equal to or greater than the

power required to rotate the load. It is selected by checking that the point

corresponding to the required operating conditions (torque and speed

output) is higher than the nominal torque versus speed curve of the

geared motor.

The required torque output of a geared motor must be within its maximum

recommended torque for continuous duty.

➜ Selecting the reduction gear ratio

Two selection criteria may be applied.

■

■

In order to avoid using numbers less than 1 where the reduction ratio is

concerned, the value 1/R is employed.

Due to the fact that it is always a reduction gear and not a «multiplier»

gear, there should be no ambiguity concerning the number used.

1/R =

P (useable)

W

The first criterion concerns the required speed output of the reduction

gear only. It is adequate for most applications and is easy to apply.

Given that :

The second criterion concerns the required usable power output of the

motor. The rotational speed of the motor is given by :

N

No = no-load speed of motor (rpm)

P

Cd = start-up torque of motor (Nm)

This gives the equation :

N = 1/2 (No +

R

= speed of motor (rpm)

= required output power (W)

Nb

N1

=

or

N1

Nb

=

1/R =

2

60

No

N1 = required speed of geared motor

Nb = basic nominal speed of motor

.M

Nm

2

N1

N

-

.n

4P

rpm

R =

A

) with A =

N1

N

30

Cd

No

Related parts for 26231941

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

SCREW SOCKET (OT08PC)

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

PANEL PLATE FOR 813

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

Controller; CTD46 Dual Display Temperature, 1/16 DIN, NEMA 4X, 110/220VAC

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1084

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1086

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1087

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1089

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1078

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1079

Manufacturer:

Crouzet USA

Datasheet: