26231941 Crouzet USA, 26231941 Datasheet - Page 97

26231941

Manufacturer Part Number

26231941

Description

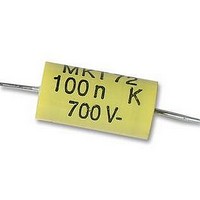

CAPACITOR, MOTOR MEDIUM TORQUE CAPACITOR, MOTOR MEDIUM TORQUE

Manufacturer

Crouzet USA

Datasheet

1.26231909.pdf

(196 pages)

Specifications of 26231941

Capacitance

0.1UF

Voltage Rating, Dc

700V

Capacitor Dielectric Type

POLYPROPYLENE

Tolerance,

10%

Tolerance, -

10%

Temp, Op. Max

85(DEGREE C)

Temp, Op. Min

0(DEGREE

- Current page: 97 of 196

- Download datasheet (6Mb)

By energising the electro-magnet with an AC current of frequency f, the

magnet will turn at a speed of f revolutions per second.

In these circumstances, a motor can start up in either direction. To

determine a particular direction, a mechanical device (anti-return)

is placed on the rotor to ensure that the motor operates only in the

direction required. There are several types of anti-return device which are

differentiated by the degree of the reverse rotation angle within which the

rotor can move.

Reversible

(Also called reversible synchronous motor)

Technology

Synchronous motors with a single-phase AC voltage and a permanent

magnet must have, for reverse operation, at least 2 stators and 2 coils.

Reverse operation can be achieved electrically using a single-pole switch.

A capacitor is used on reversible synchronous motors with 2 coils to

produce an electrical dephasing of 90° between the 2 coils. This creates a

circular revolving magnetic field. Component precision assures a perfectly

circular field and ensures silent motor operation.

➜ Wiring diagram for capacitor

The capacitor specification must be appropriate to each type of motor and

to the supply voltage. An incorrect capacitor may distort the magnetic field

and have detrimental effects on the reliability of the start-up of the motor

as well as on operational quality.

Coils

Pole pairs

Coil 1

Coil 2

Bronze sintered bearing

Rotor

The curve (motor reversing curve) below shows the limits within which the

motor will always start in relation to variation in supply voltage and the

capacitor values.

The zone within which the motor operates, ie. the area around the

nominal voltage of the capacitor, must be completely controlled by the

manufacturer.

Operating within this zone guarantees starting and operating in the

direction selected by the user.

As the diagram shows, we build our motors so that the operating zone

is as far as possible from the critical zones, whatever the nature of the

torque.

Boosted winding

Our experience in this area allows us, in certain cases and depending

on the precise specification, to operate outside this zone to produce a

higher torque and increase performance by between 30 and 80%. Please

consult us.

➜ Motor torque

2 types of torque can be distinguished.

Starting/running torque (or synchronisation torque)

This is the torque that a synchronous motor can develop both at

start-up and at synchronisation speed.

N.B:

In all technical data concerning geared motors in this catalogue, the

torque/speed curves indicate the value of the starting/running torque for

all the gearbox output speeds.

Stall torque (or desynchronisation torque)

This is the torque limit at which a synchronous motor loses its

synchronisation.

Maximum voltage

Minimum voltage

Ca : Starting/running torque

Minimum voltage of the capacitor

Nominal voltage of capacitor

Cd : Stall torque

Voltage

Zone within which the direction of the motor on starting

Zone within which the motor will not start

is not controllable

Safety zone

Speed of synchronisation

Torque

Maximum voltage of capacitor

Safety zone

Voltage of

capacitor

Speed

(rpm)

97

4

Related parts for 26231941

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

SCREW SOCKET (OT08PC)

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

PANEL PLATE FOR 813

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

Controller; CTD46 Dual Display Temperature, 1/16 DIN, NEMA 4X, 110/220VAC

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1084

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1086

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1087

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1089

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1078

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1079

Manufacturer:

Crouzet USA

Datasheet: