26231941 Crouzet USA, 26231941 Datasheet - Page 98

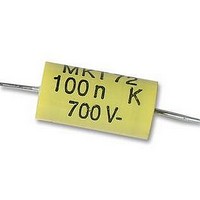

26231941

Manufacturer Part Number

26231941

Description

CAPACITOR, MOTOR MEDIUM TORQUE CAPACITOR, MOTOR MEDIUM TORQUE

Manufacturer

Crouzet USA

Datasheet

1.26231909.pdf

(196 pages)

Specifications of 26231941

Capacitance

0.1UF

Voltage Rating, Dc

700V

Capacitor Dielectric Type

POLYPROPYLENE

Tolerance,

10%

Tolerance, -

10%

Temp, Op. Max

85(DEGREE C)

Temp, Op. Min

0(DEGREE

- Current page: 98 of 196

- Download datasheet (6Mb)

4

98

The motor output shaft turns at a defined speed. This speed is generally

too high for the majority of applications.

To reduce this speed we provide users with a complete range of

gearboxes, each equipped with a series of ratios.

As a result, the motors can be used for numerous functions.

➜ Gearbox characteristics

Each gearbox has been designed for a certain workload. We have defined

its potential and its limits for optimum mechanical life.

The principal characteristic is its capacity to absorb a maximum torque in

continuous operation.

The range of gearboxes in this catalogue can be used for maximum

torques of between 0.5 and 6 N.m for long mechanical lives. The values

given are for standard products used in the normal operating conditions

specified.

In certain cases, these values can be increased if the required life is

reduced. Special cases are dealt with by our design staff.

Each gearbox nevertheless has a limit which is the

This torque, applied to the gearbox, can cause its destruction when first

used.

➜ Gearbox construction

Selecting a geared motor

Selection is made in relation to the prospective workload.

Before making a selection, it should be remembered that the motor

absorbs a certain amount of power, the absorbed power and it cannot

deliver more than a fraction of this power : the maximum is defined as the

usable power or the mechanical power.

Usable power links 2 factors.

Analysis of this formula clearly shows the function of the gearbox.

It reduces speed and increases torque since the usable power produced

by the motor is recovered by the gearbox (within the limits of normal

efficiency of course).

The torque requirement thus serves to define the gearbox (characterised

by its maximum torque) and the choice of motor depends on the speed at

which the torque is required.

The usable power should be borne in mind in all cases, as it is the basic

parameter when choosing a motor.

Motor and gearbox combination

Usable power

expressed in Watts

Gearbox

casing

Synchronous

motor

Rotor

pinion

Gearbox cover

Fixing clips between motor and

gearbox

Breakdown torque

torque and speed

expressed in N.m

Maximum torque

P = C x

Metal or moulded

wheels

Angular speed of the

output shaft expressed

in radians per second

Gearwheel pins

attached to the

gearbox casing

Output shaft

Bronze sintered

bearing

Greasing

Collar

➜ Temperature rise

Permanent magnet motors generally have relatively low efficiency and

some of the lost energy is converted into a rise in the temperature of the

motor.

We consider that this rise in temperature reaches its maximum level after

2 hours of continuous operation.

To calculate the rise, we use the method known as resistance variation.

R =

R’ = Resistance of the same coil after 2 hours of continuous motor

T1 = Ambient temperature at the end of the test.

Ta = Ambient temperature at the beginning of the test.

➜ Dielectric strength

All our products are tested to current standards.

➜ Insulation resistance

This is greater than or equal to 75,000 M

current in conditions of ambient temperature and humidity.

➜ Safety

Crouzet synchronous motors are designed and manufactured for

integration into equipment or machines meeting, for example, the

requirements of the Machinery standard : EN 60335-1 (IEC 335-1) :

Safety of domestic electrical appliances.

Integration of Crouzet synchronous motors into appliances or machines

should, as a rule, take into account the following motor characteristics :

■

■

■

■

Our motors are in general designed to conform to international

recommendations (IEC), American standards (UL - CSA) and/or

European standards (EN).

Proof of compliance with these standards and recommendations is

demonstrated by an approval (a mark or certificate of conformity granted

by an accredited body) or the manufacturer’ s declaration of conformity

(drafted in accordance with ISO/IEC 22 guidelines).

➜ EC directives

Our motors are compatible with European Community directives (Low

voltage 73/23 > 50 VAC) and in particular the aspects of electrical

safety referred to in the above standard EN 60335 (domestic electrical

appliances).

The «CE» mark on all our products is proof of this conformity.

Moreover, our products are particularly suited, for example, to applications

concerning both office equipment and medical equipment covered by

standards EN 60601 and EN 60950 respectively.

➜ Environmental protection

The modern concept of protection of the environment is an integral part of

our motors, from product design through to packaging.

Both asynchronous and synchronous motors and geared motors designed

for integration into more complex equipment by professionals, rather than

end users, are excluded from the areas of application of this directive.

Crouzet will however be pleased to provide the EMC characteristics of its

products on request.

Addinal information

Standards and approvals

Rules and regulations

Electromagnetic compatibility

(EC Directive 89/336/EEC dated 03/05/89)

R = R’ - R = Increase in coil resistance.

no earth connection,

so-called «principal insulation» motors (single insulation)

protection index : IP40

insulation class : B.

Coil resistance at ambient temperature before applying voltage to

the motor (expressed in Ohms - ).

operation.s

T =

R

R

(234.5 + Ta) - (T1 - Ta)

measured using a 500 VDC

Related parts for 26231941

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

SCREW SOCKET (OT08PC)

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

PANEL PLATE FOR 813

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

Controller; CTD46 Dual Display Temperature, 1/16 DIN, NEMA 4X, 110/220VAC

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1084

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1086

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1087

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1089

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1078

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1079

Manufacturer:

Crouzet USA

Datasheet: