1469054-1 TE Connectivity, 1469054-1 Datasheet - Page 5

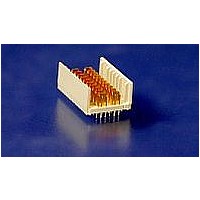

1469054-1

Manufacturer Part Number

1469054-1

Description

HM-ZD 2PR HDR SELECT LOAD

Manufacturer

TE Connectivity

Specifications of 1469054-1

Product Type

Connector

Connector Type

Header

Pcb Mounting Orientation

Vertical

Shield Material

Phosphor bronze

Module Length (mm [in])

24.90 [0.980]

Interface Type

HM-Zd

Termination Method

Press Fit

Termination End Plating

Tin-Lead over Nickel

Card Slot Pitch (mm [in])

20.3 [0.8]

Columns Per Connector

10

Centerline (mm [in])

2.50 [0.098]

Selectively Loaded

Yes

Number Of Positions

32

Contact Type

Pin

Contact Termination Type

Through Hole

Contact Configuration

ACTION PIN Post

Feedthrough Post Length (mm [in])

2.50 [0.098]

Contact Mating Area Length (mm [in])

6.35 [0.250]

Contact Base Material

Phosphor Bronze

Housing Material

Polyester GF

Number Of Pairs Per Column

2

Number Of Pairs Per Connector

20

Sequenced Pins

Yes (See Drawing)

Advancedtca Specified Product

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

3.6.

Rev C

Initial examination of product

Low level contact resistance

Low level compliant pin resistance

Insulation resistance

Withstanding voltage

Temperature rise vs current

Vibration

Mechanical shock

Durability

Mating force

Unmating force

Compliant pin insertion force

Compliant pin retention force

Minute disturbance

Receptacle cover retention

Thermal shock

Humidity-temperature cycling

Temperature life

Mixed flowing gas (mated)

Mixed flowing gas (unmated)

Dust contamination

Final examination of product

Product Qualification and Requalification Test Sequence

A.

NOTE

Two and Four Pair HM-Zd Connectors (right angle receptacle, vertical header)

Test or Examination

(a)

(b)

(c)

(d)

(e)

See paragraph 4.1.A.

Numbers indicate sequence in which tests are performed.

Perform 10 durability cycles prior to initial measurement.

Perform 125 durability cycles before, and 125 durability cycles after mixed flowing gas

testing.

Exposure interval of 5 days.

4,7,9,11,13 5,8,10,12,14 5(c),8 4,6,8,10,12,14,16,18

2,15

3,16

5,14

10

12

17

1

1

6

8

Figure 2A

3,18

4,19

6,17

15

16

20

11

13

21

2

1

7

2

9

Test Sequence (b)

Test Group (a)

3,10

4,11

6,9

12

13

3

1

2

7

11(e),13(e)

5(d),17(d)

7(e),9(e)

2,20

19

15

21

4

1

3

5

1

2

3

108-2055

6

1

2

3

5 of 8