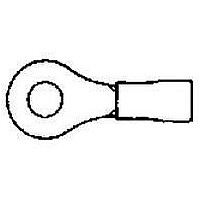

323167 TE Connectivity, 323167 Datasheet

323167

Specifications of 323167

Related parts for 323167

323167 Summary of contents

Page 1

... Design and Construction Product shall be of the design, construction and physical dim ensions specified on the applicable product drawing. ©2011 Tyco Electronics Corporation, | Indicates change a TE Connectivity Ltd. Company *Trademark All Rights Reserved TE logo is a trademark. For latest revision, visit our website at www.te.com/documents. ...

Page 2

Materials Materials used in the construction of this product shall be as specified on the applicable product drawing. 3.3. Ratings ! Current: See Figure 3 for applicable current carrying capability ! Tem perature: -75 to 150°C 3.4. Perform ance ...

Page 3

Test Description Therm al shock. Salt spray. Shall meet visual requirements, show no physical damage, and meet requirements of additional NOTE tests as specified in the Product Qualification and Requalification Test Sequence shown in Figure 2. 3.6. Product Qualification and ...

Page 4

QUALITY ASSURANCE PROVISIONS 4.1. Qualification Testing A. Specim en Selection Specim ens shall be prepared in accordance with applicable Instruction Sheets and shall be selected at random from current production. All test groups shall each consist of 10 term ...