148384-5 TE Connectivity, 148384-5 Datasheet - Page 14

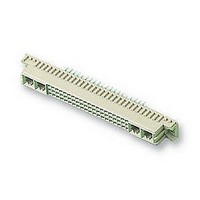

148384-5

Manufacturer Part Number

148384-5

Description

SOCKET, DIN41612, STRAIGHT, M, 24+8WAY

Manufacturer

TE Connectivity

Datasheet

1.148384-5.pdf

(18 pages)

Specifications of 148384-5

Connector Type

Pitch Spacing

No. Of Contacts

32

Gender

Receptacle

No. Of Rows

3

Rows Loaded

A + B + C

Contact Termination

Through Hole

Contact Material

Phosphor Bronze

Contact

RoHS Compliant

Pitch Spacing

2.54mm

Contact Plating

Gold

Rohs Compliant

Yes

Product Series

Type M

Mount Angle

Vertical

Post Type

Compliant Post

Din Level

II

Loaded With Single Contacts Only

Yes

Color

Gray

Toolless (flat Rock)

Yes

Termination Post Length (mm [in])

6.00 [0.236]

Solder Tail Contact Plating

Tin-Lead over Nickel

Number Of Signal Contacts

24

Contact Type

Socket

Number Of Power Or Coaxial Contacts

8

Preloaded

Yes

Contact Configuration

Coaxial, Power

Contact Base Material

Phosphor Bronze

Contact Plating, Mating Area, Material

Gold Flash over Palladium Nickel

Connector Style

Receptacle

Housing Material

Thermoplastic - GF

Ul Flammability Rating

UL 94V-0

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Pcb Thickness, Recommended (mm [in])

1.57 [0.062]

Application

Board-to-Board Power

3.9. Repair

In the event of damaged contacts or connector, the entire connector must be replaced with a new one, with the

exception of the coaxial contacts in Type M connectors which are removable (refer to Paragraph 5.6).

4. QUALIFICATIONS

Eurocard Connectors meet DIN 41612 and IEC 603--2 specifications. The connectors are also Certified by

CSA International in File LR7189 and Recognized under the Component Program of Underwriters Laboratories

Inc. (UL) in File E28476.

5. TOOLING

5.1. Application Tooling

For low--volume manufacturing, an arbor frame type applicator may be used; for high--volume manufacturing,

machine application is recommended. See Figure 13.

Power Units

14 of 18

CAUTION

DANGER

NOTE

C. Drying

When drying cleaned components and pc boards, make certain the temperature limitations of --55_ to

125_C [--70_ to 260_F] are not exceeded.

D. Soldering Guidelines

Refer to Paragraph 2.6 of this specification for instructional material that is available for establishing

soldering guidelines.

i

!

Typical Arbor Frame Press (Such as Greenerd 3A

or 3B Manual Frame Assembly—refer to 408- - 9027

for Adapter Kit when using this type press)

Consideration must be given to toxicity and safety requirements recommended on the Material Safety Data Sheet

furnished by the solvent manufacturer.

If you have a particular solvent that is not listed, consult an TE Representative before using it on these connectors.

Protect lower shroud (vertical connectors) or lower ground plane (enhanced connector) when soldering right- - angle pin

connectors.

SM- - 3 Machine

814700- - 2

Figure 13

“H” Frame Power Unit

Machine 803880- - 6

114- 9014

Rev G