148384-5 TE Connectivity, 148384-5 Datasheet - Page 7

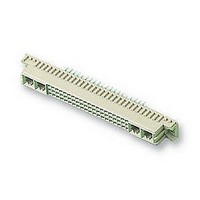

148384-5

Manufacturer Part Number

148384-5

Description

SOCKET, DIN41612, STRAIGHT, M, 24+8WAY

Manufacturer

TE Connectivity

Datasheet

1.148384-5.pdf

(18 pages)

Specifications of 148384-5

Connector Type

Pitch Spacing

No. Of Contacts

32

Gender

Receptacle

No. Of Rows

3

Rows Loaded

A + B + C

Contact Termination

Through Hole

Contact Material

Phosphor Bronze

Contact

RoHS Compliant

Pitch Spacing

2.54mm

Contact Plating

Gold

Rohs Compliant

Yes

Product Series

Type M

Mount Angle

Vertical

Post Type

Compliant Post

Din Level

II

Loaded With Single Contacts Only

Yes

Color

Gray

Toolless (flat Rock)

Yes

Termination Post Length (mm [in])

6.00 [0.236]

Solder Tail Contact Plating

Tin-Lead over Nickel

Number Of Signal Contacts

24

Contact Type

Socket

Number Of Power Or Coaxial Contacts

8

Preloaded

Yes

Contact Configuration

Coaxial, Power

Contact Base Material

Phosphor Bronze

Contact Plating, Mating Area, Material

Gold Flash over Palladium Nickel

Connector Style

Receptacle

Housing Material

Thermoplastic - GF

Ul Flammability Rating

UL 94V-0

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Pcb Thickness, Recommended (mm [in])

1.57 [0.062]

Application

Board-to-Board Power

3.2. Housing Features

Surface Finish

HASL Sn Pb

Immersion Sn

OSP

Immersion Au/Ni

Immersion Ag

Rev G

Solder Tine Plated--Through

CONTACT

ACTION

TYPE

TYPE

PIN

C. Hole Dimensions

Values specified in the following must be complied with to ensure proper performance. The drilled hole

diameter and the copper plating thickness are of major importance and must be adhered to.

A. Boardlocks

The solder tine connectors are available with boardlocks which help retain the connector onto the pc

board. Special application tooling or equipment is not required for connectors with boardlocks.

B. Mounting Ears and Standoffs

These connectors are designed with mounting ears in different thicknesses and spacing between

standoffs. Those with larger mounting ear height and closer standoff spacing do not require a seating tool

to push the ACTION PIN contacts through the pc board holes to seat the connector. Those with smaller

mounting ear height and greater standoff spacing require the use of a seating tool. See Figure 4.

3.1.A.1 and .2 for PC

Refer to Paragraph

Board Thickness

Plated--Through

Plated--Through

Plated--Through

(Type Q)

TYPE

Non--

Thickness

0.008 [.0003] Min.

0.0005 [.000020] Min.

0.0002- - 0.0005 [.000008- - .000020]

0.004- - 0.005 Ni, 0.0001- - 0.0005 Au

[.00016- - .00020] Ni, [.000004- - .000020] Au

0.0001 [.000004] Min.

Finished Hole Dia.

After Plating

(Figure 3)

[.0443--.0463]

[.0344--.0364]

[.0443--.0463]

[.0443--.0463]

1.125--1.176

0.874--0.925

1.125--1.176

1.125--1.176

DRILLED

DIAMETER

PLATING (REF)

AFTER

[.040]

[.031]

[.039]

1.02

0.80

0.99

------

PC BOARD HOLE

Figure 3

(KNOOP- - 150 Max)

[.001- - .003]

[.001- - .003]

[.001- - .003]

0.03--0.08

0.03--0.08

0.03--0.08

COPPER

------

PLATING THICKNESS

See Surface Finish/Thickness

See Surface Finish/Thickness

See Surface Finish/Thickness

Callout in Above Illustration

Callout in Above Illustration

Drilled Hole Diameter

SURFACE

FINISH

------

Pad Diameter

Copper Plating

FR- - 4 Material (Ref)

PAD (MIN DIA)

PAD (MIN DIA)

Plus 0.51 [.020]

Hole Diameter

PC BOARD

1.57 [.062]

1.57 [.062]

1.65 [.065]

114- 9014

7 of 18