63900-1 TE Connectivity, 63900-1 Datasheet - Page 17

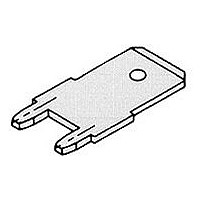

63900-1

Manufacturer Part Number

63900-1

Description

TAB, FASTON 250 PCB 032TPCUBRLP

Manufacturer

TE Connectivity

Series

250r

Datasheet

1.63900-1.pdf

(44 pages)

Specifications of 63900-1

Connector Type

Tab Boardmount

Termination Method

Quick Disconnect

Stud/tab Size

0.25 X 0.032"

Contact Material

Brass

Contact Plating

Tin

Contact

RoHS Compliant

Product Type

Terminal

Terminal Type

Tab

Mating Area Interface Dimensions (mm [in])

6.35 x 0.81 [.250 x .032]

Finish

Tin

Mount Angle

Straight

Insulation Support

Without

Pcb Hole Diameter (mm [in])

1.40 [0.055]

Dimple

Without

Tab Type

Printed Circuit Board

Stud Hole

Without

Stock Thickness (mm [in])

0.81 [0.032]

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Wave solder capable to 240°C, Wave solder capable to 260°C, Wave solder capable to 265°C

Rohs/elv Compliance History

Always was RoHS compliant

Pcb Thickness, Recommended (mm [in])

3.18 [0.125]

Packaging Method

Loose Piece

Product Facts

■

■

■

■

■

■

■

■

■

■

■

Technical Documents

Product Specification

108-6043 .070 [1.78] Diameter Terminal

108-6044 .090 [2.29] Diameter Terminal

108-6025 .125 [3.18] Diameter Terminal

108-6026 .156 [3.96] Diameter Terminal

Application Specification

114-6000 AMP-BARREL Terminals

Instruction Sheets

408-3187

408-6505

408-6553

Catalog 82159

Revised 12-07

www.tycoelectronics.com

Unique insulation

displacement technology

Eliminates wire

preparation—no stripping

or soldering

Capable of being wave-

soldered to pc board with

other components, enabling

wires to be terminated at a

more conducive time and

location

Anti-solder wicking design

Accepts a wide range of

wire sizes, solid or stranded

Available in single and

two-wire version

Reusable terminal

Available in loose-piece or

strip version

Semiautomatic insertion

machine for strip version

Simple, rugged low cost

wire insertion tool

Recognized Under

Component Recognition

Program of Underwriters

Laboratories. Inc.

— File No. E28456

R

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

Printed Circuit Board Terminals and Disconnects

AMP-BARREL Terminals

AMP-BARREL Terminals

solve the problem of

interconnecting discrete

wires to printed circuit

boards without permanently

soldering them in place,

and provide cost savings

by eliminating the need for

two-piece terminal systems,

terminal strips or expensive

space-consuming modular

connectors.

These unique insulation

displacement terminals are

suitable for most printed

circuit boards from .047

[1.19] to .125 [3.18] thick

and are mounted in a

space-saving, free-standing

manner wherever required.

AMP-BARREL Terminals

may be obtained in loose

piece or strip form for

semiautomatic machine

insertion. Upon insertion,

they are hand or wave-

soldered with other

components without fear of

solder wicking into the wire

termination area.

Termination is achieved by

placing the end of a pre-cut

unstripped wire horizontally

to the board at the top of

the AMP-BARREL Terminal.

Insertion to the proper

depth is accomplished by

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

the use of a simple, low-

cost screwdriver type tool

or low cost plastic stuffer

cap. These caps use a

standard Phillips type

screwdriver to terminate the

wire. When left in place on

the terminal they provide

strain relief and insulation.

They may be removed and

reused for field changes

and/or repairs. The high

compliancy of the terminal

assures a highly reliable,

stable interconnection

and withstands extreme

temperature, vibration

and shock.

AMP-BARREL Terminals

offer the added benefit of

accepting a wide wire

range, solid or stranded,

within the same terminal.

The .125 [3.18] diameter

AMP-BARREL Terminal

accepts a wire range of

28-18 AWG [0.08-0.8 mm

with a maximum insulation

diameter of .086 [2.18].

It is made of high strength,

high ductility, pre-tinned

phosphor bronze and

accepts one or two wires

of the same type that may

vary in size by one wire

gauge. The C-shaped

cross-slot assures a reliable

two-wire termination.

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-1106-0803

2

]

This product also offers a

wire cutoff version which

allows the wire to be placed

across the top of the

terminal where the hand tool

terminates and trims the

wire in one action.

Similarly constructed, but

of smaller size, are the

.070 [1.78] and .090 [2.29]

diameter AMP-BARREL

Terminals. These terminals

accept, respectively, wire

sizes of 28-26 AWG [0.08-

0.15 mm

insulation diameter of .036

[0.91] and 28-22 AWG [0.08-

0.4 mm

insulation diameter of .053

[1.35]. They also will accept

two wires of the same

gauge and type.

The .156 [3.96] diameter

AMP-BARREL Terminal

accepts a wire range of

24-18 AWG [0.2-0.8 mm

with a maximum insulation

diameter of .115 [2.92]. It

is made of tin-lead plated

brass and will accept one

wire per terminal.

All AMP-BARREL Terminals

are reusable. This feature is

extremely important when

correcting wiring errors,

making field repairs or

modifications.

South America: 55-11-2103-6000

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-8706-080-208

2

] with a maximum

2

] with a maximum

2

]

17