SSM2306-MINI-EVALZ Analog Devices Inc, SSM2306-MINI-EVALZ Datasheet - Page 4

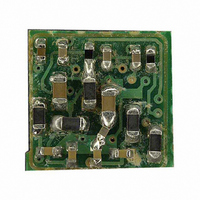

SSM2306-MINI-EVALZ

Manufacturer Part Number

SSM2306-MINI-EVALZ

Description

BOARD EVAL FOR SSM2306-MINI

Manufacturer

Analog Devices Inc

Specifications of SSM2306-MINI-EVALZ

Design Resources

Analog Audio Input, Class-D Output with ADAU1701, SSM2306, and ADP3336 (CN0162)

Amplifier Type

Class D

Output Type

2-Channel (Stereo)

Max Output Power X Channels @ Load

2.4W x 2 @ 4 Ohm

Voltage - Supply

2.5 V ~ 5 V

Operating Temperature

-40°C ~ 85°C

Board Type

Fully Populated

Utilized Ic / Part

SSM2306

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

EVAL-SSM2306-MINI

PCB LAYOUT GUIDELINES

Correct PCB layout is critical in application designs to prevent

EMI from exceeding allowable limits and to ensure that the

amplifier chip operates below the temperature limit. Follow

these guidelines carefully when designing the PCB layout.

1.

2.

3.

4.

5.

6.

Place nine vias onto the thermal pad of the amplifier. The

outer diameter of the vias should be 0.5 mm, and the inner

diameter should be 0.33 mm. Use a PCB area of at least

2 cm

layer as the heat sink (see Figure 4 and Figure 5). If internal

layers are available in the PCB, allocate an area as large as

possible to the ground planes and connect these vias to the

ground planes.

Place the EMI filtering beads (B1, B2, B3, and B4) as close

to the amplifier chip as possible.

Place the decoupling capacitors for the beads (C5, C6, C7,

and C8) as close to the amplifier chip as possible, and

connect all their ground terminals together.

Place the first decoupling capacitor for the power supply

(C9) as close to the amplifier chip as possible, and connect

its ground terminal directly to the IC GND pins (Pin 13

and Pin 16).

Place the other decoupling capacitor for the power supply

(C10) as close to the amplifier chip as possible, and connect

its ground terminal to the PCB ground area from which

the power supply traces come.

Place the bead for the power supply (B5) as close to the

amplifier chip as possible, and keep it on the same side of

the PCB as the chip.

2

or an equivalent area on the back side of the PCB

Rev. 0 | Page 4 of 8

7.

8.

9.

10. Use a solid polygon plane on the other side of the PCB for

11. Keep the PCB traces of high EMI nodes on the same side of

The SSM2306 mini evaluation board works well only if these

techniques are implemented in the PCB design to keep EMI and

amplifier temperature low.

The ferrite beads can block EMI up to 160 MHz. To

eliminate EMI higher than 160 MHz, place a low value,

small size capacitor, such as a 100 pF, 0402 size capacitor,

in parallel with the decoupling capacitors, C5, C6, C7, and

C8. Place this small capacitor at least 20 mm away from the

1 nF decoupling capacitor. Ideally, the ground terminals of

these small capacitors should be connected to the ground

terminals of the 1 nF decoupling capacitors or to the PCB

traces, which are placed as close to the output loads (the

loudspeakers) as possible. In this way, the PCB connecting

trace between these two capacitors serves as an inductor

for filtering out the high frequency component.

Ground the unconnected pins, Pin 6 and Pin 7.

Connect the GND pins, Pin 13 and Pin 16, to the thermal

pad and place grounding vias, as shown in Figure 3 and

Figure 4.

the area of the vias that are placed on the thermal pad of

the chip. See Figure 4 or Figure 5. This polygon serves as

both the EMI shielding ground plane and the heat sink for

the SSM2306.

the PCB and as short as possible. The high EMI nodes on

the SSM2306 are Pin 1, Pin 2, Pin 11, and Pin 12.