TORX147 Toshiba, TORX147 Datasheet - Page 3

TORX147

Manufacturer Part Number

TORX147

Description

RECEIVER, FIBRE OPTIC

Manufacturer

Toshiba

Datasheet

1.TORX147.pdf

(5 pages)

Specifications of TORX147

Connector Type

TosLink

Data Rate Max

15Mbps

Data Rate Min

0.1Mbps

External Depth

13.5mm

External Length / Height

19.5mm

External Width

11.5mm

High Level Output Current

-2mA

High Level Output

RoHS Compliant

Svhc

No SVHC (20-Jun-2011)

Rohs Compliant

Yes

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

TORX147

Manufacturer:

XG

Quantity:

18 760

Company:

Part Number:

TORX147L(F.T)

Manufacturer:

FUJITSU

Quantity:

9 200

Company:

Part Number:

TORX147LFT

Manufacturer:

Toshiba

Quantity:

1 793

Company:

Part Number:

TORX147PL

Manufacturer:

SANYO

Quantity:

70

Part Number:

TORX147PL

Manufacturer:

TOSHIBA/东芝

Quantity:

20 000

Company:

Part Number:

TORX147PL(FT)

Manufacturer:

Toshiba

Quantity:

1 976

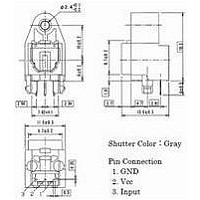

7. Board layout hole pattern

8. Precautions on Use

(1)

(2)

(3)

(4)

(5)

Maximum rating

The maximum ratings are the limit values which must not be exceeded during operation of device.

None of these rating value must not be exceeded. If the maximum rating value is exceeded, the

characteristics of devices may never be restored properly. In extreme cases, the device may be

permanently damages.

Soldering

Optical modules are comprised of internal semiconductor devices. However, in principle, optical

modules are optical components. During soldering, ensure that flux does not contact with the emitting

surface or the detecting surface. Also ensure that proper flux removal is conducted after soldering.

Some optical modules come with a protective cap. The protective cap is used to avoid malfunction

when the optical module is not in use. Note that it is not dust or waterproof.

As mentioned before, optical modules are optical components. Thus, in principle, soldering where

there may be flux residue and flux removal after soldering is not recommended. Toshiba recommend

that soldering be performed without the optical module mounted on the board. Then, after the board

has been cleaned, the optical module should be soldered on to the board manually.

If the optical module cannot be soldered manually, use non- halogen (chlorine- free) flux and make

sure, without cleaning, there is no residue such as chlorine. This is one of the ways to eliminate the

effects of flux. In such a cases, be sure to check the devices' reliability.

Noise resistance

It is believed that the use of optical transfer devices improve noise resistance. In theory, optical fiber

is not affected by noise at all. However, receiving modules which handle signals whose level is

extremely small, are susceptible to noise.

TOSLINK improve noise resistance to use a conductive case. However, the current signal output by

the optical receiving modules' photodiode is extremely small. Thus, in some environments, shielding

the case may not achieve sufficient noise resistance.

For systems which incorporate TOSLINK, Toshiba recommend testing using the actual device to

check its noise resistance.

Use a simple noise filter on TOSLINK fiber optic transceiving module's power line. If the ripple in the

power supply used is significant, reinforce the filter.

The optical module is to be used in an area which is susceptible to radiated noise, increase the

shielding by covering the optical module and the power line filter with a metallic cover.

Vibration and shock

This module is plastic sealed and has its wire fixed by resin. This structure is relatively resistant to

vibration and shock. In actual equipment, there are sometime cases in which vibration, shock, or

stress is applied to soldered parts or connected parts, resulting in lines cut. A care must be taken in

the design of equipment which will be subject to high levels of vibration.

Support pins

The TORX147(F,T) has support pins in order to fix itself to the PCB temporary. Please make the hole

for these pins in the PCB under the condition described in board layout hole pattern.

(Recommendation)

3

Unit: mm

Tolerance: ±0.05 mm

Recommended PCB thickness: 1.6 mm

TORX147(F,T)

2004-10-21