LQ022B8UD05 Sharp Microelectronics, LQ022B8UD05 Datasheet - Page 4

LQ022B8UD05

Manufacturer Part Number

LQ022B8UD05

Description

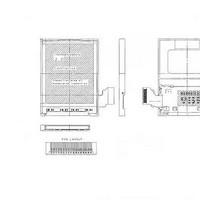

TFT Displays & Accessories 2.2 5.58cm Module 176 x RGB x 220

Manufacturer

Sharp Microelectronics

Datasheet

1.LQ022B8UD05.pdf

(27 pages)

Specifications of LQ022B8UD05

Diagonal

2.2 in

Maximum Operating Temperature

+ 70 C

Minimum Operating Temperature

- 20 C

Operating Temperature Range

- 20 C to + 70 C

Product

Displays

Touch Panel

No Touch Panel

Viewing Area (w X H)

34.848 mm x 43.56 mm

Pixel Density

176 x 220

Module Size (w X H X T)

42.1 mm x 56.6 mm x 4.2 mm

Backlighting

White

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

LQ022B8UD05

Manufacturer:

AUO

Quantity:

1 000

(8) If the LCD driver IC (COG) is exposed to light, normal operation may be impeded. It is necessary to design so that the

(4) Since this LCD panel is made of glass, dropping the module or banging it against hard objects may cause cracks or

(5) Certain materials such as epoxy resin (amine’s hardener) or silicone adhesive agent (de-alcohol or de-oxym) emits gas to

(6) Liquid crystal material will freeze below specified storage temperature range and it will not get back to normal quality even

(7) Do not expose LCD module to the direct sunlight or to strong ultraviolet light for long time.

(9) Do not disassemble the LCD module as it may cause permanent damage.

(10) As this LCD module contains components sensitive to electrostatic discharge, be sure to follow the instructions in below.

○ These specification sheets are the proprietary product of SHARP CORPORATION ("SHARP) and include materials

protected under copyright of SHARP. Do not reproduce or cause any third party to reproduce them in any form or by any

means, electronic or mechanical, for any purpose, in whole or in part, without the express written permission of SHARP.

○ The application examples in these specification sheets are provided to explain the representative applications of the device

and are not intended to guarantee any industrial property right or other rights or license you to use them. SHARP assumes no

responsibility for any problems related to any industrial property right of a third party resulting from the use of the device.

○ The device listed in these specification sheets was designed and manufactured for use in Telecommunication equipment

(terminals)

○ In case of using the device for applications such as control and safety equipment for transportation (aircraft, trains,

automobiles, etc. ), rescue and security equipment and various safety related equipment which require higher reliability and

safety, take into consideration that appropriate measures such as fail-safe functions and redundant system design should be

taken.

○ Do not use the device for equipment that requires an extreme level of reliability, such as aerospace applications,

telecommunication equipment (trunk lines), nuclear power control equipment and medical or other equipment for life support.

○ SHARP assumes no responsibility for any damage resulting from the use of the device which does not comply with the

instructions and the precautions specified in these specification sheets.

○ Contact and consult with a SHARP sales representative for any questions about this device.

(2) If the cleaning of the surface of the LCD panel is necessary, wipe it swiftly with cotton or other soft cloth. Do not use

organic solvent as it damages polarizer.

for a long time.

fragmentation.

which polarizer reacts (color change). Check carefully that gas from materials used in system housing or packaging do not hart

polarizer.

after temperature comes back within specified temperature range. Liquid crystal material will become isotropic above specified

temperature range and may not get back to normal quality. Keep the LCD module always within specified temperature range.

light is shut off when the LCD module is mounted.

① Operators

② Equipment and containers

(1) Do not scratch the surface of the polarizer film as it is easily damaged.

(3) Water droplets on polarizer must be wiped off immediately as they may cause color changes, or other defects if remained

Operators must wear anti-static wears to prevent electrostatic charge up to and discharge from human body.

Process equipment such as conveyer, soldering iron, working bench and containers may possibly generate electrostatic

[For handling and system design]

SPEC No.

LCP-05032A

NOTICE

MODEL No.

LQ022B8UD05

PAGE

1