AMMP-6408-TR1G Avago Technologies US Inc., AMMP-6408-TR1G Datasheet - Page 11

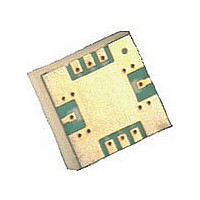

AMMP-6408-TR1G

Manufacturer Part Number

AMMP-6408-TR1G

Description

Power Amp, MMIC, 6-18GHz Pkg

Manufacturer

Avago Technologies US Inc.

Specifications of AMMP-6408-TR1G

Current - Supply

650mA

Frequency

6GHz ~ 18GHz

Gain

18dB

P1db

28.5dBm

Package / Case

8-SMD

Rf Type

LMDS, MMDS

Test Frequency

8GHz

Voltage - Supply

6V

Manufacturer's Type

Power Amplifier

Number Of Channels

1

Supply Current

650@5VmA

Frequency (max)

18GHz

Operating Supply Voltage (max)

6V

Package Type

SMT

Mounting

Surface Mount

Pin Count

8

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Noise Figure

-

Lead Free Status / Rohs Status

Compliant

Manual Assembly

• Follow ESD precautions while handling packages.

• Handling should be along the edges with tweezers.

• Recommended attachment is conductive solder

• Apply solder paste using a stencil printer or dot

• Follow solder paste and vendor’s recommendations

• Packages have been qualified to withstand a peak

Figure 22. Suggested lead-free reflow profile for SnAgCu solder paste

Package Dimensions

A

300

250

200

150

100

paste. Please see recommended solder reflow profile.

Neither Conductive epoxy or hand soldering is recom-

mended.

placement. The volume of solder paste will be depen-

dent on PCB and component layout and should be

controlled to ensure consistent mechanical and elec-

trical performance.

when developing a solder reflow profile. A stan-

dard profile will have a steady ramp up from room

temperature to the pre-heat temp. to avoid damage

due to thermal shock.

temperature of 260°C for 20 seconds. Verify that the

profile will not expose device beyond these limits.

50

0

0

8

RAMP 1

SYMBOL

A

B

DIMENSIONS ARE IN INCHES (MM)

AMMP

XXXX

YWWDNN

50

FRONT VIEW

1

7

PREHEAT

A

2

6

0.0685 (1.74)

0.198 (5.03)

MIN.

100

3

5

RAMP 2

PEAK = 250 ± 5 C

TIME (SECONDS)

150

4

0.088 (2.25)

0.213 (5.4)

REFLOW

MAX.

MELTING POINT = 218 C

SIDE VIEW

200

B

COOLING

250

0.126

(3.2)

0.029 (0.75)

300

0.059

A properly designed solder screen or stencil is required

to ensure optimum amount of solder paste is deposited

onto the PCB pads. The recommended stencil layout

is shown in Figure 2. The stencil has a solder paste

deposition opening approximately 70% to 90% of the

PCB pad. Reducing stencil opening can potentially

generate more voids underneath. On the other

hand, stencil openings larger than 00% will lead to

excessive solder paste smear or bridging across the I/O

pads. Considering the fact that solder paste thickness

will directly affect the quality of the solder joint, a

good choice is to use a laser cut stencil composed of

0.27 mm (5 mils) thick stainless steel which is capable

of producing the required fine stencil outline.

The most commonly used solder reflow method is

accomplished in a belt furnace using convection heat

transfer. The suggested reflow profile for automated

reflow processes is shown in Figure 22. This profile is

designed to ensure reliable finished joints. However, the

profile indicated in Figure will vary among different

solder pastes from different manufacturers and is shown

here for reference only.

Ordering Information

AMMP-6408 Part Number Ordering Information

Part Number

AMMP-6408-BLKG

AMMP-6408-TRG

AMMP-6408-TR2G

(1.5)

0.016 (0.40)

0.100 (2.54)

0.100 (2.54)

0.011 (0.28)

DIMENSIONAL TOLERANCE: 0.002" (0.05 mm)

4

BACK VIEW

0.114 (2.90)

0.018 (0.46)

3

0.93 (2.36)

5

Devices per

Container

0

00

500

2

6

1

7

*

0.028 (0.70)

8

Container

Antistatic bag

7” Reel

7” Reel

0.012 (0.30)

0.014 (0.365)

0.016 (0.40)