320576 TE Connectivity, 320576 Datasheet - Page 6

320576

Manufacturer Part Number

320576

Description

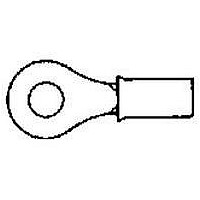

TERMINAL,PIDG R 12-10 5/16

Manufacturer

TE Connectivity

Type

Ring Tongue Terminalr

Series

320r

Specifications of 320576

Rohs Compliant

YES

Stud Size

7.94mm

Wire Gauge

10-12

Body Plating

Tin

Body Material

Copper

Insulation

Nylon

Product Depth (mm)

13.49mm

Product Length (mm)

33.58mm

Color

Yellow

Angle

Straight

Brand/series

PIDG

Contact Plating

Tin

Diameter, Insulation

0.230 "

Insulation Type

Nylon

Length, Overall

1.322 "

Material, Contact

Copper

Primary Type

Ring

Size, Stud

5⁄16 "

Width, Overall

0.531 "

Wire Size

12-10 AWG

Product

Rings

Wire Size (awg)

12-10

Stud / Tab Size

5/16 (M8)

Gender

Female

Contact Material

Copper

Insulation Material

Nylon

Voltage Rating

300 VAC

Terminal Shape

Ring Tongue

Receptacle Style

Straight

Body Style

PIDG

Barrel Type

Closed Barrel

Wire/cable Type

Regular Wire

Insulation Support

Insulation Support

Insulation Diameter (mm [in])

5.84 [.230] Max.

Stud Diameter (mm [in])

7.92 [0.312]

Shape

RING-041

Heavy Duty

No

Finish

Tin

Voltage (vac)

300

Wire/cable Size (cma)

5,180 – 13,100

Wire Range (mm [awg])

3.00-6.00² [12-10]

Tongue Material Thickness (mm [in])

1.07 [0.042]

Class

1 & 2

Government/industry Qualification

Yes

Government/industry Part Number

MS25036-113

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Loose Piece

Lead Free Status / RoHS Status

Compliant

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

D

For use with heavy duty terminals having an insulation thickness range of 1.02–1.27 [.040–.050].

of 14

16-14

The wire barrel crimp produced by the tooling (dies, heads, hand tools, pneumatic tools, or machines)

must be either a confined crescent crimp which appears as a depressed oval shape or a flat rectangular

crimp over the center of the wire barrel. The crimp must be evenly formed. Refer to Figures 4, 5, and 11.

Crescent crimp tooling produces the crescent crimp, and TETRA–CRIMP tooling produces the flat

rectangular crimp. For a tooling–to–crimp profile cross–reference, refer to Figure 10.

The dot code on the insulation must be well formed and correspond with the wire size or color code

marking on the crimping chamber of the tooling used. See Figures 4 and 5.

26-24

26-22

24 20

24-20

22 16

22-16

16 14

16-14

12 10

12-10

26

24

22

20

18

16

14

12

10

D

Natural/Yellow

Natural/White

Yellow/Yellow

Yellow/Brown

Yellow/Black

Yellow/Black

Natural/Blue

Natural/Red

Yellow/Blue

Blue/Green

Red/Green

Red/White

Blue/Blue

Red/Red

Yellow

Yellow

Yellow

White

Blue

Red

2 Dots

2 Dots

2 Dots

2 Dots

2 Dots

2 Dots

1 Dot

1 Dot

1 Dot

1 Dot

1 Dot

1 Dot

1 Dot

1 Dot

1 Dot

1 Dot

1 Dot

1 Dot

Figure 4 (End)

4.76 [.187]

3 18 [ 125]

3.18 [.125]

3 18 [ 125]

3.18 [.125]

3 18 [ 125]

3.18 [.125]

3 18 [ 125]

3.18 [.125]

6.35 [.250]

1 60 1 75 [ 063 069]

1.60-1.75 [.063-.069]

2 26 2 41 [ 089 095]

2.26-2.41 [.089-.095]

2 77 2 92 [ 109 115]

2.77-2.92 [.109-.115]

3 02 3 18 [ 119 125]

3.02-3.18 [.119-.125]

3.02-3.18 [.119-.125]

4.29-4.45 [.169-.175]

1 98 2 18 [ 078 086]

1.98-2.18 [.078-.086]

2 34 2 54 [ 092 100]

2.34-2.54 [.092-.100]

2.34-2.54 [.092-.100]

3.25-3.45 [.128-.136]

Rev