1-120524-1 TE Connectivity, 1-120524-1 Datasheet - Page 3

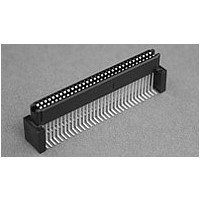

1-120524-1

Manufacturer Part Number

1-120524-1

Description

1FHR,64,50A/P,S,N,S14,15

Manufacturer

TE Connectivity

Specifications of 1-120524-1

Rohs Compliant

NO

Pcb Mount Retention

With

Pcb Mount Alignment

With

Product Type

Connector

Connector Type

Connector Assembly

Product Line

1mm FH

Ul File Number

E28476

Csa File Number

LR7189

Termination Method To Pc Board

Surface Mount

Pcb Mounting Orientation

Vertical

Pcb Mount Alignment Type

Locating Posts

Contact - Rated Current (a)

0.8

Operating Voltage Reference

AC/DC

Operating Voltage (vac)

250

Operating Voltage (vdc)

250

Tail Length (mm [in])

2.05 [0.081]

Tail Orientation

In-line

Profile Height (y-axis) (mm [in])

10.37 [0.408]

Number Of Positions

64

Number Of Columns

32

Centerline (mm [in])

1.00 [0.039]

Underplate Material Thickness (µm [?in])

1.27 [50.000]

Length (x-axis) (mm [in])

34.22 [1.347]

Width (z-axis) (mm [in])

6.04 [0.238]

Number Of Rows

2

Pcb Mount Retention Type

Locating Posts

Mating Retention

Without

Contact Base Material

Phosphor Bronze

Contact Plating, Mating Area, Material

Gold

Contact Plating, Mating Area, Thickness (µm [?in])

1.27 [50]

Tail Plating Material

Tin-Lead

Tail Plating, Thickness (µm [?in])

3.81 [150]

Underplate Material

Nickel

Contact Design

Single Beam

Pitch (mm [in])

16.00 [0.630]

Tin To Lead Ratio

93 / 7

Connector Style

Receptacle

Ul Flammability Rating

UL 94V-0

Housing Color

Black

Mating Alignment

Without

Housing Material

Thermoplastic

Stack Height (mm [in])

14.00 [0.551], 15.00 [0.591]

Differential Signaling

With

Rohs/elv Compliance

ELV compliant, 5 of 6 Compliant

Lead Free Solder Processes

Reflow solder capable to 245°C, Reflow solder capable to 260°C

Industry Standard

IEEE 1386 Mezzanine Connector

Agency/standard

UL, CSA

Ul Rating

Listed

Csa Certified

Yes

Operating Temperature (°c [°f])

-55 – +110 [-67 – +230]

Applies To

Printed Circuit Board

Board-to-board Configuration

Mezzanine

Pick And Place Cover

Without

Application Use

Board-to-Board

Contact Transmits (typical Application)

Signal (Data)

Packaging Method

Tape & Reel

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

1-120524-1

Manufacturer:

TE Connectivity AMP Connectors

Quantity:

12 000

Mechanical shock.

Durability.

Mating force.

Unm ating force.

Therm al shock.

Hum idity/tem perature cycling.

Tem perature life.

Mixed flowing gas.

Rev E

NOTE

Test Description

Shall meet visual requirements, show no physical damage, and meet requirements of additional

tests as specified in the Product Qualification and Requalification Test Sequence shown in Figure

2.

No discontinuities of 1 m icrosecond

or longer duration.

See Note.

See Note.

0.0625 kg m axim um average per

contact for 8 m m stack height.

0.0469 kg m axim um average per

contact for 15 m m stack height.

0.0234 kg m inim um average per

contact for 8 m m stack height.

0.0170 kg m inim um average per

contact for 15 m m stack height.

See Note.

See Note.

See Note.

See Note.

ENVIRONMENTAL

Figure 1 (end)

Requirem ent

EIA-364-27.

Subject m ated specim ens to 50 G's

sawtooth shock pulses of 11

m illiseconds duration. Three shocks

in each direction applied along 3

m utually perpendicular planes.

EIA-364-9.

Mate and unm ate specim ens for a

total of 100 cycles; 25 cycles before

the first m ating force test, and 75

cycles before the second m ating

force test. Cycle rate shall be a

m axim um of 300 cycles per hour.

EIA-364-13.

Measure force necessary to m ate

specim ens at a m axim um rate of

25.4 m m per m inute.

EIA-364-13.

Measure force necessary to unm ate

specim ens at a m axim um rate of

25.4 m m per m inute.

EIA-364-32.

Subject m ated specim ens to 5

cycles between -55 and 125°C with

30 m inute dwells at tem perature

extrem es and less than 1 m inute

transition tim e between

tem peratures.

EIA-364-31, Method III.

Subject m ated specim ens to 10

cycles (10 days) between 25 and

65°C at 80 to 100% RH.

EIA-364-17, Test Tim e Condition B.

Subject m ated specim ens to 110°C

for 250 hours.

EIA-364-65.

Subject unm ated specim ens to

environm ental Class II for 7 days.

Procedure

108-2246

3 of 5