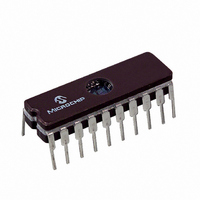

PIC16C782/JW Microchip Technology, PIC16C782/JW Datasheet - Page 77

PIC16C782/JW

Manufacturer Part Number

PIC16C782/JW

Description

IC MCU EPROM 2KX14 COMP 20CDIP

Manufacturer

Microchip Technology

Series

PIC® 16Cr

Datasheets

1.PIC16C781-ISO.pdf

(186 pages)

2.PIC16C781-ISO.pdf

(8 pages)

3.PIC16C781-ISO.pdf

(8 pages)

Specifications of PIC16C782/JW

Core Processor

PIC

Core Size

8-Bit

Speed

20MHz

Peripherals

Brown-out Detect/Reset, POR, PWM, WDT

Number Of I /o

13

Program Memory Size

3.5KB (2K x 14)

Program Memory Type

EPROM, UV

Ram Size

128 x 8

Voltage - Supply (vcc/vdd)

4 V ~ 5.5 V

Data Converters

A/D 8x8b; D/A 1x8b

Oscillator Type

Internal

Operating Temperature

0°C ~ 70°C

Package / Case

20-CDIP (0.300", 7.62mm) Window

For Use With

DVA16XP202 - ADAPTER DEVICE PIC16C781/782DM163012 - BOARD DEMO PICDEM FOR 16C781/782AC164028 - MODULE SKT PROMATEII 20SOIC/DIP

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Eeprom Size

-

Connectivity

-

Other names

Q1137459

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

9.4.1

Not all applications require a result having 8-bits of res-

olution. Some may instead, require a faster conversion

time. The ADC module allows users to make a trade-off

of conversion speed for resolution. Regardless of the

resolution required, the acquisition time is the same. To

speed up the conversion, the clock source of the ADC

module may be switched during the conversion, so that

the T

the applicable Electrical Specification). Once the switch

is made, all the following ADC result bits are invalid

(see ADC Conversion Timing in the Electrical Specifi-

cations section). The clock source may only be

switched between the three oscillator options (it cannot

be switched from/to RC). The equation to determine

the time before the oscillator must be switched for a

desired resolution is as follows:

Conversion time = 2T

Where: N = number of bits of resolution required.

Since the T

must employ some method (such as a timer, software

loop, etc.) to determine when the ADC oscillator must

be changed.

9.5

The ADC module can operate during SLEEP mode.

This requires that the ADC clock source be set to RC

(ADCS1:ADCS0 = 11). When the RC clock source is

selected, the ADC module waits one instruction cycle

before starting the conversion. This allows the SLEEP

instruction to be executed, which eliminates all digital

switching noise from the conversion. When the conver-

sion is completed the GO/DONE bit is cleared, and the

result is loaded into the ADRES register. If the ADC

interrupt is enabled, the device awakens from SLEEP.

If the ADC interrupt is not enabled, the ADC module is

turned off, although the ADON bit remains set.

When the ADC clock source is another clock option

(not RC), a SLEEP instruction causes the present con-

version to be aborted and the ADC module to be turned

off. The ADON bit remains set.

Turning off the ADC places the ADC module in its low-

est current consumption state.

Note:

2001 Microchip Technology Inc.

AD

time violates the minimum specified time (see

ADC Operation During SLEEP

AD

For the ADC module to operate in SLEEP,

the A/D clock source must be set to RC

(ADCS1:ADCS0 = 11). To perform an ADC

conversion in SLEEP, ensure the SLEEP

instruction immediately follows the instruc-

tion that sets the GO/DONE bit.

FASTER CONVERSION/LOWER

RESOLUTION TRADE-OFF

is based on the device oscillator, the user

AD

+ N • T

AD

+ (8 - N)(2T

OSC

)

Preliminary

9.6

The absolute accuracy (absolute error) specified for the

ADC converter includes the sum of all contributions for:

• Offset error

• Gain error

• Quantization error

• Integral non-linearity error

• Differential non-linearity error

• Monotonicity

The absolute error is defined as the maximum devia-

tion from an actual transition versus an ideal transition

for any code. The absolute error of the ADC converter

is specified as < ±1 LSb for ADC

device’s specified operating range). However, the

accuracy of the ADC converter degrades as V

diverges from V

For a given range of analog inputs, the output digital

code will be the same. This is due to the quantization of

the analog input to a digital code. Quantization error

is typically ± 1/2 LSb and is inherent in the analog to

digital conversion process. The only way to reduce

quantization error is to use an ADC with greater resolu-

tion of the ADC converter.

Offset error measures the first actual transition of a

code versus the first ideal transition of a code. Offset

error shifts the entire transfer function. Offset error can

be calibrated out of a system, or introduced into a sys-

tem, through the interaction of the total leakage current

and source impedance at the analog input.

Gain error measures the maximum deviation of the

last actual transition and the last ideal transition

adjusted for offset error. This error appears as a

change in slope of the transfer function. The difference

in gain error to full scale error is that full scale does not

take offset error into account. Gain error can be cali-

brated out in software.

Linearity error refers to the uniformity of the code

changes. Linearity errors cannot be calibrated out of

the system. Integral non-linearity error measures the

actual code transition versus the ideal code transition,

adjusted by the gain error for each code. Differential

non-linearity measures the maximum actual code

width versus the ideal code width. This measure is

unadjusted.

If the linearity errors are very large, the ADC may

become non-monotonic. This occurs when the digital

values for one or more input voltages are less than the

value for a lower input voltage.

ADC Accuracy/Error

PIC16C781/782

REF

.

REF

DS41171A-page 75

= V

DD

(over the

DD