B57364S209M EPCOS Inc, B57364S209M Datasheet - Page 10

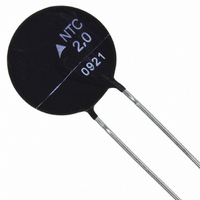

B57364S209M

Manufacturer Part Number

B57364S209M

Description

CURRENT LIMITER INRSH 2 OHM 20%

Manufacturer

EPCOS Inc

Type

NTCr

Specifications of B57364S209M

Lead Spacing

0.295" (7.50mm)

R @ 25°c

2.0 Ohm

Current - Steady State Max

12A

Tolerance

±20%

Diameter

0.825" (21mm)

Thermistor Type

NTC

Resistance

2ohm

Beta Value (k)

2900

Svhc

No SVHC (18-Jun-2010)

Beta Value Lower Limit Temperature

25°C

Body Diameter

21mm

Current Max

12A

Lead Length

32mm

Termination Style

Radial

Operating Temperature Range

- 55 C to + 170 C

Current Rating

12 Amps

Power Rating

5.1 W

Mounting Style

Through Hole

Pin Count

2

Thermal Time Constant

100s

Percentage Of Resistance Tolerance @ 25c

±20

Accuracy

±3

Product Length (mm)

Not Requiredmm

Product Height (mm)

Not Requiredmm

Thermistor Tolerance

± 20%

Thermistor Case Style

Radial Leaded

No. Of Pins

2

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

R @ Current

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

495-4114

B57364S 209M

B57364S0209M000

B57364S0209M000

Q1848236

Q3180393

Q3247542

B57364S 209M

B57364S0209M000

B57364S0209M000

Q1848236

Q3180393

Q3247542

When subjecting leads to mechanical stress, the following should be observed:

Tensile stress on leads

During mounting and operation tensile forces on the leads are to be avoided.

Bending of leads

Bending of the leads directly on the thermistor body is not permissible.

A lead may be bent at a minimum distance of twice the wire's diameter +2 mm from the solder

joint on the thermistor body. During bending the wire must be mechanically relieved at its outlet.

The bending radius should be at least 0.75 mm.

Twisting of leads

The twisting (torsion) by 180 of a lead bent by 90 is permissible at 6 mm from the bottom of the

thermistor body.

3

When thermistors are sealed, potted or overmolded, there must be no mechanical stress caused

by thermal expansion during the production process (curing / overmolding process) and during

later operation. The upper category temperature of the thermistor must not be exceeded. Ensure

that the materials used (sealing / potting compound and plastic material) are chemically neutral.

4

If cleaning is necessary, mild cleaning agents such as ethyl alcohol and cleaning gasoline are

recommended. Cleaning agents based on water are not allowed. Ultrasonic cleaning methods are

permissible.

5

In order to maintain their solderability, thermistors must be stored in a non-corrosive atmosphere.

Humidity, temperature and container materials are critical factors.

The components should be left in the original packing. Touching the metallization of unsoldered

thermistors may change their soldering properties.

Storage temperature:

Max. relative humidity (without condensation):

Solder the thermistors listed in this data book after shipment from EPCOS within the time speci-

fied:

Leaded components:

Please read Cautions and warnings and

Important notes at the end of this document.

Inrush current limiters

ICLs

Sealing and potting

Cleaning

Storage

Page 10 of 15

<95%, maximum 30 days per annum

24 months

25 C up to 45 C

B57364

S364