B57364S209M EPCOS Inc, B57364S209M Datasheet - Page 11

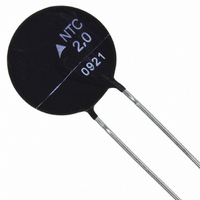

B57364S209M

Manufacturer Part Number

B57364S209M

Description

CURRENT LIMITER INRSH 2 OHM 20%

Manufacturer

EPCOS Inc

Type

NTCr

Specifications of B57364S209M

Lead Spacing

0.295" (7.50mm)

R @ 25°c

2.0 Ohm

Current - Steady State Max

12A

Tolerance

±20%

Diameter

0.825" (21mm)

Thermistor Type

NTC

Resistance

2ohm

Beta Value (k)

2900

Svhc

No SVHC (18-Jun-2010)

Beta Value Lower Limit Temperature

25°C

Body Diameter

21mm

Current Max

12A

Lead Length

32mm

Termination Style

Radial

Operating Temperature Range

- 55 C to + 170 C

Current Rating

12 Amps

Power Rating

5.1 W

Mounting Style

Through Hole

Pin Count

2

Thermal Time Constant

100s

Percentage Of Resistance Tolerance @ 25c

±20

Accuracy

±3

Product Length (mm)

Not Requiredmm

Product Height (mm)

Not Requiredmm

Thermistor Tolerance

± 20%

Thermistor Case Style

Radial Leaded

No. Of Pins

2

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

R @ Current

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

495-4114

B57364S 209M

B57364S0209M000

B57364S0209M000

Q1848236

Q3180393

Q3247542

B57364S 209M

B57364S0209M000

B57364S0209M000

Q1848236

Q3180393

Q3247542

Cautions and warnings

General

See "Important notes" at the end of this document.

Storage

Handling

Bending / twisting leads

Soldering

Please read Cautions and warnings and

Important notes at the end of this document.

Inrush current limiters

ICLs

Store thermistors only in original packaging. Do not open the package before storage.

Storage conditions in original packaging: storage temperature

humidity 75% annual mean, maximum 95%, dew precipitation is inadmissible.

Avoid contamination of thermistors surface during storage, handling and processing.

Avoid storage of thermistor in harmful environments like corrosive gases (SO

Solder thermistors after shipment from EPCOS within the time specified:

NTC thermistors must not be dropped. Chip-offs must not be caused during handling of NTCs.

Components must not be touched with bare hands. Gloves are recommended.

Avoid contamination of thermistor surface during handling.

In case of exposure of the NTC thermistors to water, electrolytes or other aggressive media,

these media can penetrate the coating and reach the surface of the ceramic. Low-ohmic or

high-ohmic behavior may occur due to the formation of an electrolyte with metals (silver/lead/tin

from metallization or solder). Low-ohmic behavior is caused by electrochemical migration,

high-ohmic behavior by dissolving of the electrode. Ineither case, the functionality of the NTC

thermistors can not be assured.

A lead (wire) may be bent at a minimum distance of twice the wire’s diameter plus 4 mm from

the component head or housing. When bending ensure the wire is mechanically relieved at the

component head or housing. The bending radius should be at least 0.75 mm.

Twisting (torsion) by 180 of a lead bent by 90 is permissible at 6 mm from the bottom of the

thermistor body.

Use resin-type flux or non-activated flux.

Insufficient preheating may cause ceramic cracks.

Rapid cooling by dipping in solvent is not recommended.

Complete removal of flux is recommended.

Leaded components: 24 months

Page 11 of 15

25 C ... +45 C, relative

x

, Cl etc).

B57364

S364