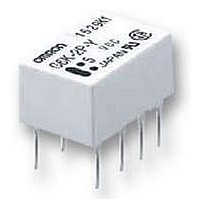

G6KU-2PY 3DC Omron, G6KU-2PY 3DC Datasheet - Page 9

G6KU-2PY 3DC

Manufacturer Part Number

G6KU-2PY 3DC

Description

RELAY, PCB, SPCO, 3VDC, LATCHING

Manufacturer

Omron

Datasheet

1.G6KU-2FY_3DC.pdf

(10 pages)

Specifications of G6KU-2PY 3DC

Contact Current Max

1A

Contact Voltage Ac Nom

125V

Contact Voltage Dc Nom

30V

Coil Voltage Vdc Nom

3V

Coil Resistance

91ohm

Coil Power Cont

100mW

Relay

RoHS Compliant

Coil Type

DC Coil

Coil Current

33mA

Contact Configuration

DPDT

Rohs Compliant

Yes

G6K

Recommended Soldering Method

Temperature indicate the surface temperature of the PCBs.

IRS Method (for surface mounting terminal models)

(1) IRS Method (Mounting Solder: Lead)

• The thickness of cream solder to be applied should be within a range between 150 and 200 µm on OMRON’s recommended PCB pattern.

• In order to perform correct soldering, it is recommended that the correct soldering conditions be maintained as shown below on the left

Visually check that the Relay is properly soldered.

■

UL approval:UL1950 (File No. E41515)

CSA approval:C22.2 No. 950 (File No. LR31928)

DPDT

side.

PCB

Correct Soldering

Approved Standards

220 to

180 to

Contact form

245

200

150

Terminal

Relay

Solder

Preheating

Land

90 to 120

G6K-2G(F/P): 3 to 12 VDC

G6K(U)-2G(F/P)-Y: 3 to 24 VDC

Incorrect Soldering

Soldering

20 to 30

Coil rating

Insufficient

amount of

solder

Time (s)

1 A at 30 VDC

0.5 A at 60 VDC

0.3 A at 125 VAC

Excessive

amount of

solder

Contact rating

(2) IRS Method (Mounting Solder: Lead-free)

Note: The temperature profile indicates the

250 max.

230

180

150

temperature of the relay terminal

section.

Upper surface of case (peak):

255˚C max.

120 max.

Preheating

6,000

Number of test operations

30 max.

Soldering

Relay

terminal

section

Time (s)

G6K

99