26231941 Crouzet USA, 26231941 Datasheet - Page 143

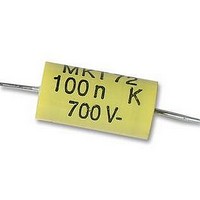

26231941

Manufacturer Part Number

26231941

Description

CAPACITOR, MOTOR MEDIUM TORQUE CAPACITOR, MOTOR MEDIUM TORQUE

Manufacturer

Crouzet USA

Datasheet

1.26231909.pdf

(196 pages)

Specifications of 26231941

Capacitance

0.1UF

Voltage Rating, Dc

700V

Capacitor Dielectric Type

POLYPROPYLENE

Tolerance,

10%

Tolerance, -

10%

Temp, Op. Max

85(DEGREE C)

Temp, Op. Min

0(DEGREE

- Current page: 143 of 196

- Download datasheet (6Mb)

Cm = Holding torque of the motor energised «two phases at a time»

➜ Comparison «2 phases» - «4 phases»

Comparison with constant voltage and resistance.

Comparison of the «2 phases» and «4 phases» motor supplied at

constant voltage

➜ Permanent magnet stepper motors

The standard connection leads AWG22 are approved to UL 80°C, 300V.

(AWG24 available on request).

➜ Hybrid stepper motors

The standard connection leads AWG22 are approved to UL 125°C, 300V.

UL 325 - 6 CSA

➜ Other hybrid steppers versions

Certain hybrid motors can be supplied in 2 phase (4 leads) or 4 phase

(8 leads). The motors are marked as follow.

A - Connections in series

Performance

Motor price

Electronics

Approvals

4 phases

Red/White

Red

Red/White

Brown

Black

2 phases

Red

Green

2 phases

High in low frequency

Low in high frequency

Low

8 transistors

Green/White

B - Connections in parallel

Black

Red/White

Red

Red/White

4 phases

High in low frequency

Supplement to cover 6 leads

4 transistors

Brown

Black

Red

Green

White

Green/White

In this catalogue, each motor shown has an 8-digit part number which is

a complete definition. To avoid any error, this part number should appear

on orders.

The stepper motor can satisfy numerous applications : to find the right

motor for your application, certain points require definition :

➜ Mechanical characteristics

Define clearly your system and your drive layout in order to evaluate

the frictions and inertias as they apply to the motor shaft (see appendix

covering mechanical aspects).

Define your transmission mode. Determine the usable torque, in dynamic

and holding form.

Determine the number of steps to accomplish and the time allocated for

this movement.

Select an operating speed.

Select a supply mode (constant voltage, two voltage levels, constant

current).

Should the motor selected produce the necessary torque at the required

frequency but in the overspeed zone, do not forget to ramp up and down

to prevent any loss of step.

Determination of conditions of use : temperature, axial and radial load,

operational frequency. In certain cases the use of a gearbox will provide

extra torque and speed; for such cases refer to curves in the catalogue to

indicate the usable power and 3/15speed available.

➜ Specific requirements

Elements to provide to define a motor correctly if you do not find the

product you need in the catalogue:

Dimensions, step angle, resistance, number of phases, lead length, type

of connector, supply type, operating frequency, required torque, operating

cycle.

But if your application requires special shafts or other mechanical

or electric adaptations (pinions, connectors etc) our staff are at

your disposal (for significant quantities). We point out as well that

numerous adaptations exist as standard or semi-standard versions.

Notes

How to define your requirements

143

5

Related parts for 26231941

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

SCREW SOCKET (OT08PC)

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

PANEL PLATE FOR 813

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

Controller; CTD46 Dual Display Temperature, 1/16 DIN, NEMA 4X, 110/220VAC

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1084

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1086

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1087

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1089

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1078

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1079

Manufacturer:

Crouzet USA

Datasheet: