26231941 Crouzet USA, 26231941 Datasheet - Page 96

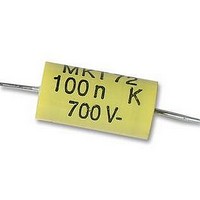

26231941

Manufacturer Part Number

26231941

Description

CAPACITOR, MOTOR MEDIUM TORQUE CAPACITOR, MOTOR MEDIUM TORQUE

Manufacturer

Crouzet USA

Datasheet

1.26231909.pdf

(196 pages)

Specifications of 26231941

Capacitance

0.1UF

Voltage Rating, Dc

700V

Capacitor Dielectric Type

POLYPROPYLENE

Tolerance,

10%

Tolerance, -

10%

Temp, Op. Max

85(DEGREE C)

Temp, Op. Min

0(DEGREE

- Current page: 96 of 196

- Download datasheet (6Mb)

4

96

To produce a certain number of movements within a well defined time

period - in this case, the motor is used as a time base.

To produce a rotation movement requiring relatively low torque at

reasonable cost.

The Crouzet synchronous range consists of the following motor types :

➜ 1 Single direction

Either :

■

■

(We will see below how to ensure the correct direction of rotation).

In special applications it is possible to dispense with the anti-return totally

(SAR version). In this case, the motor may rotate in a clockwise direction.

➜ 2 Reversible

The motor rotates in either a clockwise or an anti-clockwise direction. The

direction of rotation is controlled by a capacitor.

This motor is characterised by a constant speed of rotation which is

independent of the load but linked to the supply frequency.

A synchronous motor maintains its speed of rotation until an overload

occurs.

When overload occurs, the motor loses synchronisation, ie. it stops and

develops an oscillation (vibration).

➜ Speed of rotation

This basic characteristic can be calculated as below :

Speed (in rpm) = 60 x f (en Hz)

f Hz : The frequency of the AC voltage through the coil.

P

Example :

A motor equipped with 5 pole pairs would give :

V = 60 x 50 = 600 rpm using a 50 Hz supply

and

V = 60 x 60 = 720 720 rpm using US supply (60 Hz)

Some principles of synchronous motors

Why choose a synchronous motor ?

How to select from the Crouzet range

Definition of a synchronous motor

Therefore the speed of rotation of a synchronous motor is defined

by its construction.

clockwise (CW or SA)

or anti-clockwise (ACL or SI)

: The number of pole pairs in the motor

(1 pair = 1 North Pole + 1 South Pole).

5

5

P

➜ Construction of a permanent magnet synchronous motor

Single direction

Technology

Our single direction motors are only available with a mechanical anti-

return. This assembly offers the double advantage of being a relatively

simple technical design while offering good performance.

The permanent magnet rotor has at its periphery a number of alternating

NORTH and SOUTH poles equal to the number of poles on the stator.

The latter, energised by a single coil connected to an AC supply,

produces a magnetic asymmetry which positions the rotor when stopped

in such a way that it is attracted by an oscillating torque when the current

is switched on.

This start-up condition would cause the motor to turn in either direction

if a mechanical device called an «anti-return» did not define and impose

the direction of rotation.

➜ Principle of operation

The principle assumes an electro-magnet : a permanent NS magnet

rotates around axis O in the air-gap of the electro-magnet, perpendicular

to the lines of magnetic force.

Let us suppose that this moving permanent magnet reaches the position

marked in figure 1. If the relative positions of the electro-magnet poles are

as shown in this figure, the magnet will be repelled and tend to oscillate

around an equilibrium position at 180° to direction S’ N ’ .

When the permanent magnet is just past this position (figure 2) and the

polarity of the electro-magnet is reversed, the magnet will be repelled and

return to its previous position, and so on.

Stator cover

Casing poles S.N.S.N.S.N

Cover poles N.S.N.S.N.S

Figure 1

Anti-return

Rotor

Stator casing

Induction coil

Figure 2

Related parts for 26231941

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

SCREW SOCKET (OT08PC)

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

PANEL PLATE FOR 813

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

Controller; CTD46 Dual Display Temperature, 1/16 DIN, NEMA 4X, 110/220VAC

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1084

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1086

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1087

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1089

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1078

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1079

Manufacturer:

Crouzet USA

Datasheet: