26231941 Crouzet USA, 26231941 Datasheet - Page 72

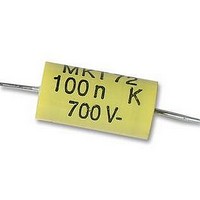

26231941

Manufacturer Part Number

26231941

Description

CAPACITOR, MOTOR MEDIUM TORQUE CAPACITOR, MOTOR MEDIUM TORQUE

Manufacturer

Crouzet USA

Datasheet

1.26231909.pdf

(196 pages)

Specifications of 26231941

Capacitance

0.1UF

Voltage Rating, Dc

700V

Capacitor Dielectric Type

POLYPROPYLENE

Tolerance,

10%

Tolerance, -

10%

Temp, Op. Max

85(DEGREE C)

Temp, Op. Min

0(DEGREE

- Current page: 72 of 196

- Download datasheet (6Mb)

2

72

1.1. Composition of the driving part:

Brushless motors comprise 3 main elements:

- A fixed part, the stator, which has three groups of coils, called the

three phases of the motor. These coils operate as electromagnets and

generate various orientations of magnetic field regularly distributed

around the central shaft of the motor.

- A rotating part, the rotor, which has permanent magnets. Like the

needle of a compass, these magnets permanently drive the rotor to try

to align itself with the magnetic field of the stator. For optimum service

life of the motor, the rotor is mounted on ball bearings.

- Three "Hall effect" magnetic sensors. These sensors provide informa-

tion on the position of the rotor magnets at all times.

1.2. The integrated control electronics:

Crouzet brushless motors incorporate their control electronics as

standard. The control electronics control the phases of the motor,

regulate the speed and incorporate the encoder function.

Basic concepts

Brushless motors and geared motors

Principle

Inputs: On/off

Direction Speed

Torque (*)

Outputs:

Encoder

Direction info (*)

Torque info (*)

Electronic

plate

Hall effect

sensors

electronics

Control

Stator

(coils)

Control of

coils

Stator

Magnetic field

Rotor

N

S

Rotor

Field

Ball bearings

Hall effect

(magnets)

sensors

Rotor

Rotational

movement

- The control electronics determine the position of the rotor using the

Hall effect sensors. The electronics deduce from the sensors the orien-

tation to give to the magnetic field of the stator. During rotation, they

control the three coils to regularly adjust the orientation of the field to

the position of the rotor, in order to drive it in the direction chosen by

the user.

- By modulating the current in the coils, the electronics can accelerate

or slow down the motor and thus regulate its speed. They can also

orient the magnetic field in order to brake the movement of the rotor to

bring it to a standstill.

- By limiting the current in the coils, the electronics can also limit the

torque of the motor, and activate the corresponding output

- The electronics also generate the outputs of the built-in encoder using

the Hall effect sensors.

2.1. What is 4-quadrant regulation?

The four zones of a torque/speed diagram are known as ‘quadrants’:

- A positive speed represents clockwise rotation, and a negative speed

anti-clockwise

- A positive torque represents motor operation, and a negative torque

brake operation.

1-quadrant regulation operates in a single direction of rotation, with no

possibility of braking. In the event of overspeed, the regulator cuts off

the current until the motor is braked by the load

The principle is identical for 2-quadrant regulation, but in both direc-

tions of rotation. This operating mode is offered as an option on

Crouzet brushless motors, when required by a specific application.

4-quadrant regulation also operates in both directions of rotation, but

also allows braking. In the event of overspeed, the motor is involved in

the braking and the system quickly loses speed.

All Crouzet brushless motors have 4-quadrant regulation as

standard.

Speed regulation

Reverse operation

2

3

Motor

Brake

Speed axis

4

1

Clockwise

Related parts for 26231941

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

SCREW SOCKET (OT08PC)

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

PANEL PLATE FOR 813

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

Controller; CTD46 Dual Display Temperature, 1/16 DIN, NEMA 4X, 110/220VAC

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1084

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1086

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1087

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1089

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1078

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1079

Manufacturer:

Crouzet USA

Datasheet: