26231941 Crouzet USA, 26231941 Datasheet - Page 18

26231941

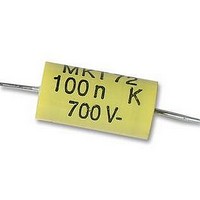

Manufacturer Part Number

26231941

Description

CAPACITOR, MOTOR MEDIUM TORQUE CAPACITOR, MOTOR MEDIUM TORQUE

Manufacturer

Crouzet USA

Datasheet

1.26231909.pdf

(196 pages)

Specifications of 26231941

Capacitance

0.1UF

Voltage Rating, Dc

700V

Capacitor Dielectric Type

POLYPROPYLENE

Tolerance,

10%

Tolerance, -

10%

Temp, Op. Max

85(DEGREE C)

Temp, Op. Min

0(DEGREE

- Current page: 18 of 196

- Download datasheet (6Mb)

1

18

Many applications call for a high start-up torque. The D.C. motor, by its

very nature, has a high torque vs. falling speed characteristic and this

enables it to deal with high starting torques and to absorb sudden rises in

load easily. The speed of the motor adjusts to the load. Furthermore, the

D.C. motor is an ideal way of achieving the miniaturisation designers are

constantly seeking because the efficiency it gives is high compared with

other designs.

➜ Safety

Crouzet D.C. motors are designed and manufactured for integration into

equipment or machines which meet, for example, the requirements of the

machinery standard :

EN 60335-1 (IEC 335-1, “Safety of domestic electrical appliances”).

Integration of Crouzet D.C. motors into equipment or machines should, as

a rule, take the following motor characteristics into account :

EC LOW VOLTAGE DIRECTIVE 73/23/EEC OF 19/02/73 :

Crouzet D.C. motors and geared motors are not covered by this directive

(LVD 73/23/EEC applies to voltages greater than 75 VDC).

➜ Electromagnetic compatibility (EMC)

Crouzet Ltd can provide the EMC characteristics of the various types of

product on request.

EC DIRECTIVE 89/336/EEC OF 03/05/89,

“ELECTROMAGNETIC COMPATIBILITY” :

D.C. motors and geared motors are considered as components meant

for integration into other equipment and therefore fall outside its field of

application. However, these products are designed in compliance with

EMC characteristics and consequently can be incorporated in equipment

having to comply with the EMC directive.

The motor unit is selected according to the required output power.

Depending on the required speed, a direct motor or a geared motor is

selected.

Speeds 1,000 to 5,000 rpm

Speeds below 500 rpm

The gearbox is selected depending on the maximum required torque and

the duty cycle.

This motor follows linear laws of operation and because of this it is

easier to fully exploit its characteristics compared to synchronous or

asynchronous motors.

Some principles of direct current (D.C.) motors

Why choose a D.C. motor ?

Design of Crouzet D.C. motors

How to select from the Crouzet range

Definition of the D.C. motor

■

■

■

■

no ground connection

so-called «principal insulation» motors (single insulation)

protection index : IP00 to IP40

insulation classes : A to F

Direct motor

Geared motor

}

(see the catalogue page

details for individual motor

types)

➜ Composition of a D.C. motor

The stator is formed by a metal carcass and one or more magnets

that create a permanent magnetic field inside the stator. At the rear of

the stator are the brush mountings and the brush gear which provide

electrical contact with the rotor.

The rotor is itself formed by a metal carcass carrying coils which are

interconnected at the commutator at the rear of the rotor.

The commutator and brush assembly then select the coil through which

the electric current passes in the opposite direction.

Principle of operation

Whatever the complexity of the rotor coil windings, once they are

energised, they may be represented in the form of a ferromagnetic

cylinder with a solenoid wrapped around it.

The wire of the solenoid is in practice the wire bundle located in

each groove of the rotor. The rotor, when energised, then acts as an

electromagnet, the magnetic field following the axis separating the wires

of the solenoid in the direction of the current which flows through them.

The motor, therefore, consists of fixed permanent magnets (the stator) a

moving magnet (the rotor) and a metal carcass to concentrate the flux

(the motor body).

By the attraction of opposite poles and repulsion of like poles, a torque

then acts on the rotor and makes it turn. This torque is at a maximum

when the axis between the poles of the rotor is perpendicular to the axis

of the poles of the stator.

As soon the rotor begins to turn, the fixed brushes make and break

contact with the rotating commutator segments in turn.

The rotor coils are then energised and de-energised in such a way that as

the rotor turns, the axis of a new pole of the rotor is always perpendicular

to that of the stator. Because of the way the commutator is arranged, the

rotor is in constant motion, no matter what its position. Fluctuation of

the resultant torque is reduced by increasing the number of commutator

segments, thereby giving smoother rotation.

By reversing the power supply to the motor, the current in the rotor coils,

and therefore the north and south poles, is reversed. The torque which

acts on the rotor is thus reversed and the motor changes its direction of

rotation. By its very nature, the D.C. motor is a motor with a reversible

direction of rotation.

Rotor

Commutator

Brush

Coil

Rotor

Stator

Magnet

Shaft

Related parts for 26231941

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

SCREW SOCKET (OT08PC)

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

PANEL PLATE FOR 813

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

Controller; CTD46 Dual Display Temperature, 1/16 DIN, NEMA 4X, 110/220VAC

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1084

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1086

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1087

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1089

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1078

Manufacturer:

Crouzet USA

Datasheet:

Part Number:

Description:

11R1079

Manufacturer:

Crouzet USA

Datasheet: