5745919-2 TE Connectivity, 5745919-2 Datasheet - Page 3

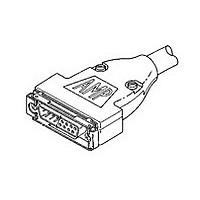

5745919-2

Manufacturer Part Number

5745919-2

Description

CABLE CLAMP KIT,SZ 2

Manufacturer

TE Connectivity

Type

Cable Clampr

Specifications of 5745919-2

Rohs Compliant

YES

Product Type

Backshell/Cable Clamp

Cable Clamp Type

Two-Piece RFI/EMI Shield

Shell Size

2

Grommets

Without

Slide Latch

Without

Thread Size

4-40

Id Letter

H

Shielded

Yes

Cable Exit Angle

180°

Cable Insulation Diameter (mm [in])

9.53 [0.375]

Number Of Positions

15

Cable Clamp Material

Die Cast

Shield Plating

Bright Nickel over Copper

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Individual Kit

Physical Shock (b)

Cable Pullout (c)

Circular Jacket Cable Flexing (c)

Thermal Shock (b)

Industrial Mixed Flowing Gas

NOTE

Rev A

Test Description

(a) Maximum rated current that can be carried by this product is limited by maximum operating

(b) Shall remain mated and show no evidence of damage, cracking or chipping.

(c)

temperature of CCA&A and cable per Para 3.3.B. and temperature rise of contacts as

determined by the Product Specifications in Para 2.1.E.. Variables which shall be considered

for each application are: wire size, connector size, contact material, and ambient

temperature.

Cable pullout and flex pertains to samples with crimp ferrules only

No discontinuities greater than 1.0

microsecond.

CCA&A shall have no physical

damage electrical discontinuities

greater than 1.0 microsecond.

CCA&A shall have no physical

damage electrical discontinuities

greater than 1.0 microsecond.

Dielectric withstanding voltage.

ENVIRONMENTAL

Figure 1 (end)

Requirement

Subject mated connector to 50 G's

half-sine in 11 milliseconds; 3

shocks in each direction applied

along the 3 mutually perpendicular

Test Specification 109-26-1.

Apply 50 pounds; AMP or Spec

109-46

100 cycles at a rate of or 12 to 14

cycles per minute;

Test Specification 109-20.

Subject mated connectors to 5

cycles between -55° to 105° C for

zinc die cast C.C.; -55° to 85° C for

plated plastic C.C. Maximum

temperature not to exceed Para

Test Specification 109-22.

Subject mated connectors to class

III industrial mixed flowing gas for

10 day duration per

Test Specification 109-85-3.

planes total 18 shocks;

3.3.B.;

Procedure

108-40032

3 of 6