5745919-2 TE Connectivity, 5745919-2 Datasheet - Page 4

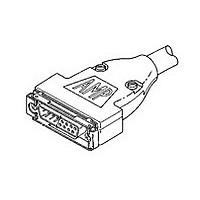

5745919-2

Manufacturer Part Number

5745919-2

Description

CABLE CLAMP KIT,SZ 2

Manufacturer

TE Connectivity

Type

Cable Clampr

Specifications of 5745919-2

Rohs Compliant

YES

Product Type

Backshell/Cable Clamp

Cable Clamp Type

Two-Piece RFI/EMI Shield

Shell Size

2

Grommets

Without

Slide Latch

Without

Thread Size

4-40

Id Letter

H

Shielded

Yes

Cable Exit Angle

180°

Cable Insulation Diameter (mm [in])

9.53 [0.375]

Number Of Positions

15

Cable Clamp Material

Die Cast

Shield Plating

Bright Nickel over Copper

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Individual Kit

3.6.

4.

4.1.

Rev A

Accessories Qualification and Requalification Tests and Sequences

QUALITY ASSURANCE PROVISIONS

Qualification Testing

A.

B.

C.

Sample Selection

Connector housings and contacts shall be prepared in accordance with applicable Instruction

Sheets. They shall be selected at random from current production. All test groups shall each

consist of a minimum of six double ended cable assemblies with appropriate shielding hardware.

The cable used shall be a single shielded jacketed cable with enough conductors that a minimum

of 75% of the contacts in the connector are terminated.

Each cable shall be 6 feet + .5 inches long as specified in the cable length figure of AMP Test

Specification 109-90.

All contacts shall be crimped in accordance with Application Specification 114-10000.

Test Sequence

Qualification inspection shall be verified by testing samples as specified in Figure 2.

Acceptance

1.

and lower one-sided statistical tolerance limits for 99% reliability at 95% confidence, as

follows. Let Xbar and s denote the sample average and standard deviation, respectively, of

the test data. Let k denote the normal distribution one-sided tolerance factor for 95%

confidence and 99% reliability. The value of k varies with sample size. Values of k are given

in various tables, for example, NBS Handbook 91, Factors for One-Sided Tolerance Limits

for Normal Distribution. Suitability of the normal distribution for representing the data shall be

verified with normal probability plots, goodness of fit tests, etc.

Test results from development on pre-qualification samples will be used to determine upper

Then the upper one-sided tolerance limit for 99% reliability at 95% confidence is given by

Xbar + ks. The interpretation of this tolerance limit is as follows: based on the test data, and

assuming a normal distribution for the test data, we can be 95% confident that 99% of the

population of values represented by the sample data will not exceed Xbar + ks. For any test

parameter for which there is specified an upper requirement which is not to be exceeded,

satisfactory performance of the product is achieved when the value of Xbar + ks does not

exceed the requirement value.

Test or Examination

Examination of Product

Dielectric Withstanding Voltage

Insulation Resistance

Shielding Effectiveness

Vibration

Physical Shock

Cable Pullout

Thermal Shock

Circular Jacket Cable Flexing

Industrial Mixed Flowing Gas

NOTE

(a) See Para 4.1.A.

(b) Numbers indicate sequence in which tests are performed.

Figure 2

3, 8

2, 7

4, 9

1

1

5

6

Test Sequence (b)

Test Group (a)

2, 4

2

1

3

4, 10

3, 9

2, 8

3

1

5

6

7

108-40032

4 of 6