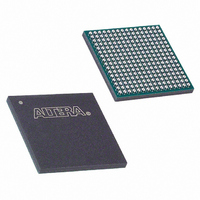

EPM2210F256C5N Altera, EPM2210F256C5N Datasheet - Page 43

EPM2210F256C5N

Manufacturer Part Number

EPM2210F256C5N

Description

IC MAX II CPLD 2210 LE 256-FBGA

Manufacturer

Altera

Series

MAX® IIr

Specifications of EPM2210F256C5N

Programmable Type

In System Programmable

Delay Time Tpd(1) Max

7.0ns

Voltage Supply - Internal

2.5V, 3.3V

Number Of Logic Elements/blocks

2210

Number Of Macrocells

1700

Number Of I /o

204

Operating Temperature

0°C ~ 85°C

Mounting Type

Surface Mount

Package / Case

256-FBGA

Voltage

2.5V, 3.3V

Memory Type

FLASH

Number Of Logic Elements/cells

2210

Cpld Type

FLASH

No. Of Macrocells

1700

No. Of I/o's

204

Propagation Delay

7.5ns

Global Clock Setup Time

1.2ns

Frequency

304MHz

Supply Voltage Range

3V To 3.6V

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Features

-

Other names

544-1354

EPM2210F256C5N

EPM2210F256C5N

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

EPM2210F256C5N

Manufacturer:

ALTBRA

Quantity:

40

Company:

Part Number:

EPM2210F256C5N

Manufacturer:

ALTERA

Quantity:

1 235

Part Number:

EPM2210F256C5N

Manufacturer:

ALTERA/阿尔特拉

Quantity:

20 000

Introduction

IEEE Std. 1149.1 (JTAG) Boundary-Scan Support

Table 3–1. MAX II JTAG Instructions (Part 1 of 2)

© October 2008 Altera Corporation

MII51003-1.6

SAMPLE/PRELOAD

EXTEST

BYPASS

USERCODE

IDCODE

HIGHZ

JTAG Instruction

(1)

(1)

This chapter discusses how to use the IEEE Standard 1149.1 Boundary-Scan Test (BST)

circuitry in MAX II devices and includes the following sections:

■

■

All MAX

circuitry that complies with the IEEE Std. 1149.1-2001 specification. JTAG boundary-

scan testing can only be performed at any time after V

been fully powered and a t

use the JTAG port for in-system programming together with either the Quartus

software or hardware using Programming Object Files (.pof), JamTM Standard Test

and Programming Language (STAPL) Files (.jam), or Jam Byte-Code Files (.jbc).

The JTAG pins support 1.5-V, 1.8-V, 2.5-V, or 3.3-V I/O standards. The supported

voltage level and standard are determined by the V

The dedicated JTAG pins reside in Bank 1 of all MAX II devices.

MAX II devices support the JTAG instructions shown in

“IEEE Std. 1149.1 (JTAG) Boundary-Scan Support” on page 3–1

“In System Programmability” on page 3–4

00 0000 0101

00 0000 1111

11 1111 1111

00 0000 0111

00 0000 0110

00 0000 1011

Instruction Code

®

II devices provide Joint Test Action Group (JTAG) boundary-scan test (BST)

3. JTAG and In-System Programmability

CONFIG

Allows a snapshot of signals at the device pins to be captured and

examined during normal device operation, and permits an initial data

pattern to be output at the device pins.

Allows the external circuitry and board-level interconnects to be

tested by forcing a test pattern at the output pins and capturing test

results at the input pins.

Places the 1-bit bypass register between the TDI and TDO pins,

which allows the BST data to pass synchronously through selected

devices to adjacent devices during normal device operation.

Selects the 32-bit USERCODE register and places it between the

TDI and TDO pins, allowing the USERCODE to be serially shifted

out of TDO. This register defaults to all 1’s if not specified in the

Quartus II software.

Selects the IDCODE register and places it between TDI and TDO,

allowing the IDCODE to be serially shifted out of TDO.

Places the 1-bit bypass register between the TDI and TDO pins,

which allows the boundary scan test data to pass synchronously

through selected devices to adjacent devices during normal device

operation, while tri-stating all of the I/O pins.

amount of time has passed. MAX II devices can also

Description

CCIO

CCINT

of the bank where it resides.

Table

and all V

3–1.

CCIO

MAX II Device Handbook

banks have

®

II