MAX1276EVKIT Maxim Integrated, MAX1276EVKIT Datasheet - Page 16

MAX1276EVKIT

Manufacturer Part Number

MAX1276EVKIT

Description

Data Conversion IC Development Tools Evaluation Kit/Evaluation System for the MAX1070/71/72/75#79/MAX1224/25/MAX1274#79

Manufacturer

Maxim Integrated

Series

MAX1276, MAX1278r

Datasheet

1.MAX1276EVKIT.pdf

(21 pages)

Specifications of MAX1276EVKIT

Interface Type

QSPI, Serial (SPI, Microwire)

Problem: Measurements show high levels

of distortion.

• Verify AIN levels are within the specified ranges for

• When using on-board buffers, verify that ACIN inputs

• Verify the input signal generators have the expected

• Use a spectrum analyzer to verify signal integrity

• Verify the input signal generators have the expected

• If experimenting with R1 and R2 or C1 values (or

• Verify SPI inputs are correct and meet all timing and

Problem: FFT measurements show excessive

signal spreading.

• If using coherent sampling techniques (preferred),

• If using noncoherent sampling techniques, be sure

• In all cases, be certain that your FFT routines are

• Verify that master-clock-derived SPI input signals

MAX1276 Evaluation Kit/Evaluation System

16

the part, both with respect to supply and reference

values. Failure to do so results in clipping of the dif-

ferential input. This is usually observed as excessive

harmonic content.

and AIN outputs are within the linear range of the

amplifiers. Inspect waveforms for signs of clipping.

level of purity. Many signal generators require exter-

nal filters to provide true 12-bit purity. Also ensure

the signal generators are operating in their linear

range. It may be necessary to adjust the resistive

feedback paths around the internal buffers if more

signal gain is required.

both at the source and at the inputs of the ADC

under test.

termination; the EV kit is set up with 50Ω termination.

dual input capacitors), verify that the buffers or

external sources are maintaining stability. Also verify

that the source impedance is not interacting with the

test device. (Refer to the product datasheet for typi-

cal THD performance vs. source impedance.)

level requirements. Verify periodic sampling is as

expected when performing dynamic measurements.

check the following. Ensure signal and master clock

generators have the required frequency resolution to

maintain full coherency. Synchronize all coherent

sources using proper connection techniques; be

certain proper locking is achieved.

to apply proper windowing functions to the data.

operating correctly and are being supplied with

enough samples to show the desired level of resolu-

tion and accuracy.

are in fact coherent and periodic.

______________________________________________________________________________________

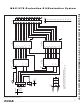

A deserializer board can be used to convert the serial-

output format of the MAX1276 family to a parallel data

format. Use of a deserializer greatly simplifies testing

when using a logic analyzer. The circuit shown in

8 has been used successfully with the EV kit. It consists

of a shift register (CD74AC164E) followed by a transpar-

ent latch (MC74AC373N). The deserializer board should

be powered from the VLOGIC and DGND pads.

The deserializer requires an additional set of signals to

drive its circuitry and the logic analyzer. An example

set of SPI and deserializer waveforms is detailed in

Figure

to 16-bit digital word lengths. The MAX1276 family pro-

vides 12-bit digital outputs. The serial digital output of

the test device, D[11:0], can be read in parallel format

as B[11:0]. Be sure to configure the logic analyzer

accordingly.

9. The deserializer board shown can support up

Deserializer Board (Optional)

Deserializer Signals

Figure