TLP200G-1 STMicroelectronics, TLP200G-1 Datasheet - Page 12

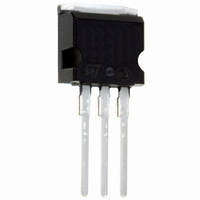

TLP200G-1

Manufacturer Part Number

TLP200G-1

Description

IC OVP TRIPOLAR TELECOM I2PAK

Manufacturer

STMicroelectronics

Datasheet

1.TLP200G-1.pdf

(14 pages)

Specifications of TLP200G-1

Voltage - Working

180V

Voltage - Clamping

200V

Technology

Mixed Technology

Number Of Circuits

1

Applications

Telecommunications

Package / Case

I²Pak, TO-262 (3 straight leads + tab)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Power (watts)

-

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

TLP200G-1

Manufacturer:

ST

Quantity:

12 500

SOLDERING RECOMMENDATION

The soldering process causes considerable ther-

mal stress to a semiconductor component. This

has to be minimized to assure a reliable and ex-

tended lifetime of the device. The PowerSO-10

package can be exposed to a maximum tempera-

ture of 260°C for 10 seconds. However a proper

soldering of the package could be done at 215°C

for 3 seconds. Any solder temperature profile

should be within these limits. As reflow techniques

are most common in surface mounting, typical

heating profiles are given in Figure 1,either for

mounting on FR4 or on metal-backed boards. For

each particular board, the appropriate heat profile

has to be adjusted experimentally. The present

proposal is just a starting point. In any case, the fol-

lowing precautions have to be considered :

TLPxxM/G/G-1

Fig. 1 : Typical reflow soldering heat profile

12/14

- always preheat the device

- peak temperature should be at least 30 °C

- thermal capacity of the base substrate

higher than the melting point of the solder

alloy chosen

250

200

150

100

50

0

0

Temperature ( C)

Epoxy FR4

40

board

Metal-backed

board

245 C

215 C

80

o

o

o

120

Preheating

160

Time (s)

200

Voids pose a difficult reliability problem for large

surface mount devices. Such voids under the

package result in poor thermal contact and the

high thermal resistance leads to component fail-

ures. The PowerSO-10 is designed from scratch to

be solely a surface mount package, hence symme-

try in the x- and y-axis gives the package excellent

weight balance. Moreover, the PowerSO-10 offers

the unique possibility to control easily the flatness

and quality of the soldering process. Both the top

and the bottom soldered edges of the package are

accessible for visual inspection (soldering menis-

cus).

Coplanarity between the substrate and the pack-

age can be easily verified. The quality of the solder

joints is very important for two reasons : (I) poor

quality solder joints result directly in poor reliability

and (II) solder thickness affects the thermal resis-

tance significantly. Thus a tight control of this pa-

rameter results in thermally efficient and reliable

solder joints.

Soldering

240

280

Cooling

320

360