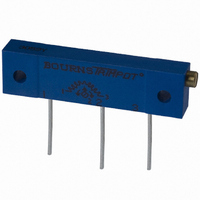

3059Y-1-500LF Bourns Inc., 3059Y-1-500LF Datasheet - Page 11

3059Y-1-500LF

Manufacturer Part Number

3059Y-1-500LF

Description

TRIMPOT 50 OHM 1.25"REC CER MT

Manufacturer

Bourns Inc.

Series

3059 - Sealedr

Specifications of 3059Y-1-500LF

Temperature Coefficient

±100ppm/°C

Resistance (ohms)

50

Termination Style

PC Pin

Power (watts)

1W

Tolerance

±10%

Number Of Turns

22

Adjustment Type

Side Adjustment

Resistive Material

Cermet

Mounting Type

Chassis Mount

Package / Case

Rectangular - 1.250" L x 0.190" W x 0.315" H (31.75mm x 4.83mm x 8.00mm)

Track Resistance

50ohm

No. Of Turns

22

Resistance Tolerance

± 10%

Power Rating

1W

Potentiometer Mounting

Through Hole

Resistance

50 Ohms

Operating Temperature Range

- 55 C to + 150 C

Element Type

Cermet

Dimensions

6.10 mm W x 31.75 mm L

Product

Trimmers

Taper

Linear

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

- Current page: 11 of 172

- Download datasheet (7Mb)

float height gives the appropriate fuel volume signal to the fuel gauge. For this

reason, a custom fuel card is generally designed for each fuel tank model.

The first fuel senders were wirewound construction. However, in many instances

these units suffered from wire wear and breakages. The resistance profile of the

wirewound fuel sender also changed as the wire wore at different rates and

positions of the float arm. These problems were overcome with the introduction

of the thick-film fuel card. A variable resistor is achieved by tapping the resistor

traces with segmented conductor tracks creating a step-function output as shown

in Figure 6. If the wiper contact were to run directly on the cermet resistor, as in a

potentiometer, the required product life specification of at least 1 million wet

cycles would not be achieved. A tight resistance tolerance of each partial resistor

is achieved by laser trimming.

As the fuel card (resistor element) is immersed in fuel, its chemical resistance is of

great importance. The introduction of low-sulphur fuels for environmental

reasons has placed additional demands on conductor metallurgies.

Typical Fuel Card Designs

Termination

Figure 7: Fuel card design overview (Dual track design)

Figure 9: Single track design

Specifications are typical and dependent on

the manufacturing method, materials, size

and shape of the part.

pads

resistor

Feeder

Resistor traces

Ceramic Substrate

(Alumina)

Tape selector track

(Segmented conductor)

Collector track

(Solid conductor)

Figure 10: Linear track design

Trends

Figure 5: Typical fuel level indication circuit

Figure 6: Example of step-function output

Figure 8: Dual track design

sender

300

250

200

150

100

V

level

Fuel

50

in

cc

0

0

the fuel level sender market

Fuel Card Resistance Profile

10

Feeder resistor

20

Steps

30

Fuel gauge

40

50

60

9

Related parts for 3059Y-1-500LF

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

POT 500K OHM 1-1/4" RECT CERM MT

Manufacturer:

Bourns Inc.

Datasheet:

Part Number:

Description:

POT 100 OHM 1-1/4" RECT CERM MT

Manufacturer:

Bourns Inc.

Datasheet:

Part Number:

Description:

POT 10K OHM 1-1/4" RECT CERM MT

Manufacturer:

Bourns Inc.

Datasheet:

Part Number:

Description:

POT 100K OHM 1-1/4" RECT CERM MT

Manufacturer:

Bourns Inc.

Datasheet:

Part Number:

Description:

POT 1.0K OHM 1-1/4" RECT CERM MT

Manufacturer:

Bourns Inc.

Datasheet:

Part Number:

Description:

POT 50K OHM 1-1/4" RECT CERM MT

Manufacturer:

Bourns Inc.

Datasheet:

Part Number:

Description:

POT 2.0K OHM 1-1/4" RECT CERM MT

Manufacturer:

Bourns Inc.

Datasheet:

Part Number:

Description:

POT 200K OHM 1-1/4" RECT CERM MT

Manufacturer:

Bourns Inc.

Datasheet:

Part Number:

Description:

POT 20K OHM 1-1/4" RECT CERM MT

Manufacturer:

Bourns Inc.

Datasheet:

Part Number:

Description:

POT 1.0M OHM 1-1/4" RECT CERM MT

Manufacturer:

Bourns Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Bourns, Inc.

Datasheet:

Part Number:

Description:

11mm Potentiometer

Manufacturer:

Bourns, Inc.

Datasheet: