LMD18201T/NOPB National Semiconductor, LMD18201T/NOPB Datasheet - Page 7

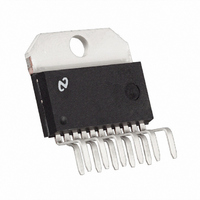

LMD18201T/NOPB

Manufacturer Part Number

LMD18201T/NOPB

Description

IC H BRIDGE 3A 55V TO220-11

Manufacturer

National Semiconductor

Specifications of LMD18201T/NOPB

Applications

DC Motor Driver, Stepper Motor Driver, H Bridge

Number Of Outputs

1

Current - Output

3A

Voltage - Supply

12 V ~ 55 V

Operating Temperature

-40°C ~ 125°C

Mounting Type

Through Hole

Package / Case

TO-220-11 (Bent and Staggered Leads)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Voltage - Load

-

Lead Free Status / Rohs Status

RoHS Compliant part

Electrostatic Device

Other names

*LMD18201T

*LMD18201T/NOPB

LMD18201T

*LMD18201T/NOPB

LMD18201T

Application Information

below the Absolute Maximum Rating of the device. When

operating the chip at supply voltages above 40V a voltage

suppressor (transorb) such as P6KE62A is recommended

from supply to ground. Typically the ceramic capacitor can

be eliminated in the presence of the voltage suppressor.

Note that when driving high load currents a greater amount

of supply bypass capacitance (in general at least 100 µF per

Amp of load current) is required to absorb the recirculating

currents of the inductive loads.

CURRENT LIMITING

Current limiting protection circuitry has been incorporated

into the design of the LMD18201. With any power device it is

important to consider the effects of the substantial surge

currents through the device that may occur as a result of

shorted loads. The protection circuitry monitors the current

through the upper transistors and shuts off the power device

as quickly as possible in the event of an overload condition

(the threshold is set to approximately 10A). In a typical motor

driving application the most common overload faults are

caused by shorted motor windings and locked rotors. Under

these conditions the inductance of the motor (as well as any

series inductance in the V

the magnitude of a current surge to a safe level for the

LMD18201. Once the device is shut down, the control cir-

cuitry will periodically try to turn the power device back on.

This feature allows the immediate return to normal operation

once the fault condition has been removed. While the fault

remains however, the device will cycle in and out of thermal

shutdown. This can create voltage transients on the V

supply line and therefore proper supply bypassing tech-

niques are required.

The most severe condition for any power device is a direct,

hard-wired (“screwdriver”) long term short from an output to

ground. This condition can generate a surge of current

through the power device on the order of 15 Amps and

require the die and package to dissipate up to 500W of

power for the short time required for the protection circuitry

to shut off the power device. This energy can be destructive,

particularly at higher operating voltages (

precautions are in order. Proper heat sink design is essential

and it is normally necessary to heat sink the V

(pin 6) with 1 square inch of copper on the PC board.

INTERNAL CHARGE PUMP AND USE OF

BOOTSTRAP CAPACITORS

To turn on the high-side (sourcing) DMOS power devices,

the gate of each device must be driven approximately 8V

more positive than the supply voltage. To achieve this an

internal charge pump is used to provide the gate drive volt-

age. As shown in (Figure 5), an internal capacitor is alter-

nately switched to ground and charged to about 14V, then

switched to V

than V

running internal 300 kHz oscillator. The rise time of this drive

voltage is typically 20 µs which is suitable for operating

frequencies up to 1 kHz.

S

. This switching action is controlled by a continuously

S

thereby providing a gate drive voltage greater

CC

supply line) serves to reduce

(Continued)

>

30V) so some

CC

supply pin

CC

7

For higher switching frequencies, the LMD18201 provides

for the use of external bootstrap capacitors. The bootstrap

principle is in essence a second charge pump whereby a

large value capacitor is used which has enough energy to

quickly charge the parasitic gate input capacitance of the

power device resulting in much faster rise times. The switch-

ing action is accomplished by the power switches them-

selves (Figure 6). External 10 nF capacitors, connected from

the outputs to the bootstrap pins of each high-side switch

provide typically less than 100 ns rise times allowing switch-

ing frequencies up to 500 kHz.

INTERNAL PROTECTION DIODES

A major consideration when switching current through induc-

tive loads is protection of the switching power devices from

the large voltage transients that occur. Each of the four

switches in the LMD18201 have a built-in protection diode to

clamp transient voltages exceeding the positive supply or

ground to a safe diode voltage drop across the switch.

The reverse recovery characteristics of these diodes, once

the transient has subsided, is important. These diodes must

come out of conduction quickly and the power switches must

be able to conduct the additional reverse recovery current of

the diodes. The reverse recovery time of the diodes protect-

ing the sourcing power devices is typically only 70 ns with a

FIGURE 5. Internal Charge Pump Circuitry

FIGURE 6. Bootstrap Circuitry

01079306

www.national.com

01079307