XCMD2116L1 SQUARE D, XCMD2116L1 Datasheet - Page 208

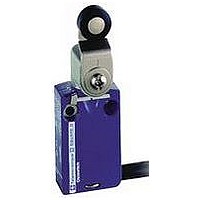

XCMD2116L1

Manufacturer Part Number

XCMD2116L1

Description

LIMIT SWITCH, 1NO.1NC, 240VAC, 250VDC, 6A

Manufacturer

SQUARE D

Datasheet

1.XCKD2102N12.pdf

(246 pages)

Specifications of XCMD2116L1

Actuator Style

Roller Lever

Operating Force Max

0.1N

Switch Operation

(ON)

Contact Voltage Ac Max

240V

Contact Voltage Dc Max

250V

Contact Current Ac Max

6A

Contact Current Dc Max

6A

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

- Current page: 208 of 246

- Download datasheet (20Mb)

Limit Switches

9007C Heavy Duty Industrial

Technical Information

208

© 1997–2007 Schneider Electric All Rights Reserved

Slow break contacts—The speed of transfer of the moveable contacts is dependent on the speed of the

operator. The amount of travel of the moveable contacts is also dependent on the amount of travel by the

operator. Slow make and break contacts have the same trip and reset points, and do not have the

differential travel common to snap switches.

Snap action contacts—The speed of transfer of the moveable contacts is not dependent on the speed

of the operator. The amount of travel of the moveable contacts is also not dependent on the amount of

travel by the operator. The movement of the moveable contacts are determined by a preset travel, after

this point is reached, the contacts will trip. Snap action contacts have different trip and reset points, the

difference is identified as “differential.”

Flexible operators—Flexible resilient or elastic operators, i.e., wobble sticks, do not ensure direct

opening/positive opening action.

Isolated contacts—Single-pole double-throw (SPDT) contacts with four terminals which have two

isolated contact bars mechanically linked. No polarity restrictions apply. Different (isolated) power

supplies can also be applied.

Same polarity—Single-pole double throw (SPDT) contacts with four terminals that require the supply to

be applied with the same polarity (i.e., L1 or +) on the same side of the contact bar. Two different

supplies are not allowed in this configuration. (The loads should always be on the same side of the

contact bar.)

Direct opening contact (also known as positive opening contacts)—A normally closed contact

element coupled with the switch actuator via a non-resilient (non-elastic) member so that full contact

opening is obtained when the actuator is moved through the direct opening travel by applying a direct

opening force. The contact element will shear open in the event of sticking contacts or broken springs.

Proper fusing of the control circuit is required. Direct opening contacts meet IEC 60947-5-1

requirements.

Direct opening travel (also known as positive opening travel)—Minimum travel from the actuator

free position to the position where the direct opening operation is completed. Usually longer than the

normal pre-travel.

Reed contacts—Contact mechanism consists of a set of contacts hermetically sealed in a glass

envelope and actuated by a magnet attached to the operator. This sealed construction keeps

contaminants out of the contact area, making the reed switch the ideal switch for low voltage, low current

circuits such as programmable controllers.

NOTE: Because reed switches are operated by a magnet, they should not be installed in areas where strong magnetic

fields may be present. The devices should always be checked for proper operation after installation.

Definition

Polarity

Opposite polarities should not be

connected to the contacts of one limit

switch unless the limit switch is

specifically designed for such service

(isolated contacts—no polarity). See

page 209.

Incorrect

Correct

Power sources

Power from different sources should not

be connected to the contacts of one limit

switch unless the switch is specifically

designed for such service (isolated

contacts—no polarity).

DC

AC

Incorrect

IM

CR

03/2007

Related parts for XCMD2116L1

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

Pushbutton, Non-Illum'd Red "STOP", Momentary, 1NO-1NC, Square 30mm, 10A, 600V

Manufacturer:

SQUARE D

Datasheet:

Part Number:

Description:

KITS,TWIDO? PROGRAMMABLE CONTROLLERS,KITS,TWIDOPACK STARTER KIT - ADVANCED LEVEL,PROGRAMMABLE CONTROLLERS,TWIDO? PROGRAMMABLE CONTROLLERS ,SQUARE D

Manufacturer:

SQUARE D

Part Number:

Description:

LAMPS,INDICATOR,STACKABLE,LAMPS, STACKABLE INDICATOR,VISUAL INDICATING SIGNALS,XVB SERIES INDICATING BANKS ,SQUARE D

Manufacturer:

SQUARE D

Part Number:

Description:

LAMPS,INDICATOR,STACKABLE,LAMPS, STACKABLE INDICATOR,VISUAL INDICATING SIGNALS,XVB SERIES INDICATING BANKS ,SQUARE D

Manufacturer:

SQUARE D

Datasheet:

Part Number:

Description:

I/O EXTENDER MODULE 4 D IN & 2 D OUTPUT

Manufacturer:

SQUARE D

Datasheet:

Part Number:

Description:

CB ACCESSORY, UNDERVOLTAGE TRIP 48V DC

Manufacturer:

SQUARE D

Datasheet: