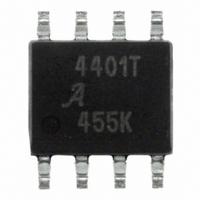

A4401KL-T Allegro Microsystems Inc, A4401KL-T Datasheet - Page 11

A4401KL-T

Manufacturer Part Number

A4401KL-T

Description

IC QUASI FLYBACK CONVERTER 8SOIC

Manufacturer

Allegro Microsystems Inc

Datasheet

1.A4401KLTR-T.pdf

(17 pages)

Specifications of A4401KL-T

Display Type

Vacuum Fluorescent (VF)

Current - Supply

2.3mA

Voltage - Supply

7 V ~ 40 V

Operating Temperature

-40°C ~ 125°C

Mounting Type

Surface Mount

Package / Case

8-SOIC (3.9mm Width)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Interface

-

Configuration

-

Digits Or Characters

-

A4401

then:

Because of flux fringing effects, the above air gap

should be modified, according to the following formu-

las. Given:

where l

mate air gap, and G is the bobbin width (the effective

winding width).

then the total air gap can now be found:

Note that most ferrite core manufacturers provide a

limited number of air gap sizes. It is therefore recom-

mended to select a standard size. Size is indicated

in terms of the Al factor, which is expressed in L/N

units. The Al factor can be derived from the above two

formulae.

To minimize flux leakage effects, it is recommended

that the air gap should be located on the center limb.

If, however, a distributed air gap is used, the air gap

figure should be divided by two.

Some applications require an AC filament output.

Typically this may be a center tapped winding with

the center tap held at some bias voltage. During the

MOSFET off-time, the output voltage of the control

winding is simply reflected through the turns ratio of

the magnetics.

During the on-time of the MOSFET, the windings are

driven as a forward converter because there is no rec-

tifying diode to isolate this action. The voltage during

this interval is simply the battery voltage transformed

by the turns ratio of the filament winding and the pri-

mary winding. This means that as the battery voltage

varies, there will be a variation in the filament voltage.

However, this variation will be less than those aris-

g

(approx) is the previously calculated approxi-

F =

I

I

g

g

(approx) =

I

=

g

(approx)

I

A

g

(approx) × (1 + F)

½

e

× ln

μ

O

× A

⎛

⎜ ⎜

⎝

Automotive Quasi-Resonant Flyback Control IC

L

I

g

P

e

(approx)

2 × G

× N

P

²

.

⎞

⎟ ⎟

⎠

.

.

(27)

(28)

(29)

2

ing in other converter topologies because, during the

MOSFET off-time, the voltage is regulated.

The voltage amplitude across the filament winding is:

where:

It is probably desirable to optimize the filament volt-

age at nominal battery conditions; for example, at

V

Due to the low voltage out, the number of integer turn

combinations is limited. So, the filament voltage may

not be exact. The turns range may only be 2 or 3.

The magnetic wire sizing for each winding is deter-

mined by the ampere-turns ratio as a proportion of the

total ampere-turns of all the windings. The amount of

bobbin area available for the windings is influenced by

the amount of insulation required, the winding con-

struction technique, and the packing density of the cir-

cular wire. A conservative utilization factor is 0.5, that

is, 50% of the bobbin window area filled with copper.

The rms current of each winding has to be determined.

The worst case condition is at minimum input voltage

and maximum load.

The primary winding current is identical to the current

flowing in the current sense resistor (see the Current

Sense Resistor Selection section). The current in each

of the other output windings can be found as follows.

Given:

N

N

output winding, and

V

output.

BAT

SF

S1

OUT1

= 13.5 V.

is the number of turns on the main controlled

is the number of turns on the filament winding,

is the output voltage of the main controlled

V

FIL

=

V

BAT

I

PK

×

115 Northeast Cutoff, Box 15036

Allegro MicroSystems, Inc.

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

=

N

N

SF

P

2 × I

D'(max)

+ V

OUT

OUT1

×

,

N

N

SF

S1

,

(30)

(31)

11