LNK403EG Power Integrations, LNK403EG Datasheet - Page 9

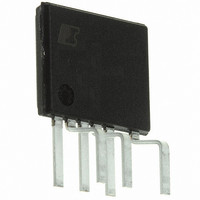

LNK403EG

Manufacturer Part Number

LNK403EG

Description

IC LED DVR TRIAC 12W DIM SIP-7C

Manufacturer

Power Integrations

Series

LinkSwitch®-PHr

Datasheet

1.LNK403EG.pdf

(20 pages)

Specifications of LNK403EG

Constant Current

Yes

Topology

PWM

Number Of Outputs

1

Internal Driver

Yes

Type - Primary

*

Type - Secondary

*

Frequency

62kHz ~ 70kHz

Voltage - Supply

90 V ~ 265 V

Voltage - Output

*

Mounting Type

Through Hole

Package / Case

7-SIP, 6 Leads, Exposed Pad, Formed Leads

Operating Temperature

-40°C ~ 150°C

Current - Output / Channel

*

Internal Switch(s)

Yes

Efficiency

85%

Operating Supply Voltage

36 V

Maximum Supply Current

2.25 mA

Maximum Power Dissipation

12 W

Maximum Operating Temperature

+ 125 C

Mounting Style

Through Hole

Minimum Operating Temperature

- 20 C

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

596-1300-5

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Part Number:

LNK403EG

Manufacturer:

POWER

Quantity:

20 000

provides tighter clamp voltage tolerance than a Zener clamp.

The RCD clamp is more cost effective than the Zener clamp but

requires more careful design to ensure that the maximum drain

voltage does not exceed the power MOSFET breakdown

voltage. These V

internal MOSFET, a V

designs, giving the best PFC and regulation performance.

Series Drain Diode

An ultra-fast or Schottky diode in series with the drain is

necessary to prevent reverse current flowing through the

device. The voltage rating must exceed the output reflected

voltage, V

average primary current and have a peak rating equal to the

maximum drain current of the selected LinkSwitch-PH device.

Line Voltage Peak Detector Circuit

LinkSwitch-PH devices use the peak line voltage to regulate the

power delivery to the output. A capacitor value of 1 mF to 4.7 mF

is recommended to minimize line ripple and give the highest

power factor (>0.9), smaller values are acceptable but result in

lower PF and higher line current distortion.

Operation with Phase Controlled Dimmers

Dimmer switches control incandescent lamp brightness by not

conducting (blanking) for a portion of the AC voltage sine wave.

This reduces the RMS voltage applied to the lamp thus

reducing the brightness. This is called natural dimming and the

LinkSwitch-PH LNK403-409 devices when configured for

dimming utilize natural dimming by reducing the LED current as

the RMS line voltage decreases. By this nature, line regulation

performance is purposely decreased to increase the dimming

range and more closely mimic the operation of an incandescent

lamp. Using a 49.9 kW REFERENCE pin resistance selects

natural dimming mode operation.

Leading Edge Phase Controlled Dimmers

The requirement to provide flicker-free output dimming with low

cost, TRIAC-based, leading edge phase dimmers introduces a

number of trade-offs in the design.

Due to the much lower power consumed by LED based lighting

the current drawn by the overall lamp is below the holding

current of the TRIAC within the dimmer. This causes undesirable

behaviors such as limited dimming range and/or flickering. The

relatively large impedance the LED lamp presents to the line

allows significant ringing to occur due to the inrush current

charging the input capacitance when the TRIAC turns on. This

too can cause similar undesirable behavior as the ringing may

cause the TRIAC current to fall to zero and turn off.

To overcome these issues two circuits, the Active Damper and

Passive Bleeder, are incorporated. The drawback of these

circuits is increased dissipation and therefore reduced efficiency

of the supply so for non-dimming applications these

components can simply be omitted.

Figure 8(a) shows the line voltage and current at the input of a

leading edge TRIAC dimmer with Figure 8(b) showing the

resultant rectified bus voltage. In this example, the TRIAC

conducts at 90 degrees.

www.powerint.com

OR

. The current rating should exceed two times the

OR

limits are based on the BV

OR

of 60 V to 100 V is typical for most

DSS

rating of the

Figure 8.

Figure 9 shows undesired rectified bus voltage and current with

the TRIAC turning off prematurely and restarting.

If the TRIAC is turning off before the end of the half-cycle

erratically or alternate half AC cycles have different conduction

angles then flicker will be observed in the LED light due to

variations in the output current. This can be solved by including

a bleeder and damper circuit.

Dimmers will behave differently based on manufacturer and

power rating, for example a 300 W dimmer requires less

dampening and requires less power loss in the bleeder than a

600 W or 1000 W dimmer due to different drive circuits and

TRIAC holding current specifications. Line voltage also has a

significant impact as at high line for a given output power the

input current and therefore TRIAC current is lower but the peak

inrush current when the input capacitance charges is higher

creating more ringing. Finally multiple lamps in parallel driven

from the same dimmer can introduce more ringing due to the

increased capacitance of parallel units. Therefore when testing

dimmer operation verify on a number of models, different line

voltages and with both a single driver and multiple drivers in

parallel.

-150

-250

-350

350

250

150

-50

350

300

250

200

150

100

50

50

0

0.5

0

(a) Ideal Input Voltage and Current Waveforms for a Leading Edge

TRIAC Dimmer at 90° Conduction Angle. (b) Resultant Waveforms

Following Rectification of TRIAC Dimmer Output.

50

50

100

100

Conduction Angle (°)

Conduction Angle (°)

LNK403-409EG/413-419EG

150

150

200

200

Voltage

Current

250

250

300

300

PI-5983-060810

Voltage

Current

PI-5984-060810

350

350

400

400

Rev. B 11/10

0.35

0.25

0.15

0.05

-0.05

-0.15

-0.25

-0.35

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

9