FSCT07A-UH5 STMicroelectronics, FSCT07A-UH5 Datasheet - Page 8

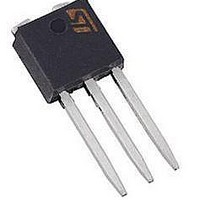

FSCT07A-UH5

Manufacturer Part Number

FSCT07A-UH5

Description

IC CONTROLLER FAN SPEED IPPAK

Manufacturer

STMicroelectronics

Type

18 Line 3-5 Volt Low Capacitance SCSI Active Terminatorr

Datasheet

1.FSCT07A-UH5.pdf

(11 pages)

Specifications of FSCT07A-UH5

Applications

Fan Controller

Number Of Outputs

1

Voltage - Supply

9 V ~ 15 V

Operating Temperature

0°C ~ 125°C

Mounting Type

Surface Mount

Package / Case

IPPAK-5

Product

Fan / Motor Controllers / Drivers

Operating Supply Voltage

7 V

Supply Current

3 mA

Mounting Style

Through Hole

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Current - Output

-

Voltage - Load

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

FSCTxxA-UH5

Two components should be used to improve the heat exchange between the FSCT die and the heat sink,

that the temperature has to be monitored. These components are:

Several clips can be used depending on the heat sink type:

Fig. 9: IPPAK mounted with a Saddle clip.

It can be noticed that the thickness of the IPPAK package (2.3 +/- 0.1 mm) is similar to those of SOT-32 and

SOT-82 (2.55 +/- 0.15 mm). The same clips can so be used for all these packages.

3.3 Temperature measurement error

Firstly, the time constant between a temperature variation on the external side on the IPPAK copper tab,

and the silicon die is in the range of a few hundred of milliseconds. As temperature phenomena are ex-

tremely slow for the targeted applications (the temperature of a MOSFET heat sink, increases typically with

an 1°C per second rate, in a power supply), the FSCT is able to react immediately to over-heating events.

Moreover, the very low junction to case thermal resistance (3 °C/W) reduces as much as possible the tem-

perature measurement error.

We calculate, in the following, this error considering both the package and the heatsink-Tab interface ther-

mal resistances ( figure 11 ).

Several companies offer adhesive and isolating

materials to be used as interface between elec-

tronic devices and a heat sink. These interfaces

can be provided with a shape dedicated for the

Tab foot print. For the IPPAK package, users could

choose a shape dedicated for SOT-32, SOT-82 or

even TO-126 or TO-220 packages (the more can

do the less).

8/11

A thermal interface pad, in order to reduce the impact of air voids on the thermal impedance and to en-

sure an electrical insulation (if needed)

A clip to push the IPPAK against the heat sink and then to reduce also the interface thermal imped-

ance.

Saddle clips (cf. figure 9 ) for slim heat sink;

U-clips (cf. figure 10 ) for thick heat sink

Dedicated clips for special shape heat sink.

Fig. 10: IPPAK mounted with a U-clip.

Fig. 11: IPPAK Heatsink Interface.

Interface

Interface