HFBR-0573 Avago Technologies US Inc., HFBR-0573 Datasheet - Page 11

HFBR-0573

Manufacturer Part Number

HFBR-0573

Description

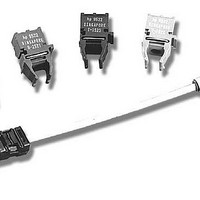

Fiber Optics, Evaluation Kit

Manufacturer

Avago Technologies US Inc.

Datasheet

1.HFBR-0573.pdf

(14 pages)

Specifications of HFBR-0573

Silicon Core Number

HFBR-5601/5602, HFCT-5611/5612

Features

One Fully Assembled GBIC Test Fixture And Literature

Tool / Board Applications

Transceivers

Main Purpose

Interface, Ethernet

Embedded

No

Utilized Ic / Part

HFBR-5601, HFBR-5602, HFCT-5611, HFCT-5612

Primary Attributes

GBIC Gigabit Ethernet or Fibre Channel Applications

Secondary Attributes

Hot Pluggable

Description/function

Fiber Optic Kit

Development Tool Type

Hardware / Software - Eval/Demo Board

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

For Use With/related Products

HFBR-560x, HFCT-561x

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Contains lead / RoHS non-compliant

Long Wavelength GBIC: HFCT-5611

Transmitter Section

The transmitter section consists of a 1300 nm MQW

Fabry Perot Laser in an optical subassembly (OSA),

which mates to the fiber optic cable. The Laser OSA is

driven by a custom, silicon bipolar IC which converts

differential PECL logic signals (ECL referenced to a +5

V supply) into an analog drive current to the laser.

The laser driver IC incorporates temperature

compensation and feedback from the OSA to maintain

constant output power and extinction ratio over the

operating temperature range.

Receiver Section

The receiver includes a PIN photodiode mounted

together with a custom, silicon bipolar transimpedance

preamplifier IC, in an OSA. The OSA interfaces to a

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can cause catastrophic damage to the device. Limits apply to each

parameter in isolation, all other parameters having values within the recommended operating conditions. It should not be

assumed that limiting values of more than one parameter can be applied to the product at the same time. Exposure to the

absolute maximum ratings for extended periods can adversely affect device reliability.

Recommended Operating Conditions

Transceiver Electrical Characteristics

(T

Notes:

1. See Figure 1 for measurement point.

2. Maximum current is specified at V

3. Hot plug above actual steady state current.

4. Total T

Parameter

Data Input Voltage

Differential Input Voltage

Relative Humidity

Parameter

Case Temperature

Parameter

Power Dissipation

11

Storage Temperature

Supply Voltage

Transmitter

Ambient Operating Temperature

Supply Voltage

Supply Current

Surge Current

A

= 0°C to +60°C, V

X

+ R

X

.

CC

= 4.75 V to 5.25 V)

CC

= maximum @ maximum operating temperature and end of life.

RH

I

I

P

Symbol

T

V

V

TX_DAT

±TX_DAT

Symbol

T

T

V

V

Symbol

TX

SURGE

DISS

S

A

CASE

DD

DD

DD

DD

+ I

T

R

T

R

RX

Min.

-40

-0.5

-0.5

Min.

0

Min.

5

4.75

custom silicon bipolar circuit that provides post-

amplification and quantization. The post-amplifier

includes a Signal Detect circuit that provides TTL

compatible logic-low output in response to the

detection of a usable input optical signal.

Eye Safety Design

The laser driver is designed to be Class 1 eye safe

(CDRH21 CFR(J), IEC 60825-1) under a single fault

condition.

There are three key elements to the safety circuitry: a

monitor diode, a window detector circuit, and direct

control of the laser bias. The window detection circuit

monitors the average optical power using the photo

diode in the laser OSA. If a fault occurs such that the dc

bias circuit cannot maintain the preset conditions

within ±20%, TX_FAULT (Pin 10) will be asserted (high).

Note: Under any single fault, the laser optical output

power will remain within Class 1 eye safe limits.

5.0

200

1.00

Typ.

Typ.

Typ.

Max.

+85

6.0

2000

95

Max.

+60

+75

5.25

Max.

+30

1.58

V

300

DD

T

Unit

mV p-p

Unit

mA

Unit

mA

°C

V

V

%

°C

°C

V

W

Notes

Notes

1

2

Notes

3

4