350199-1 TE Connectivity, 350199-1 Datasheet - Page 4

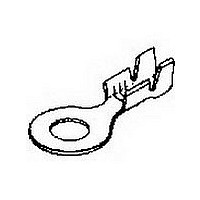

350199-1

Manufacturer Part Number

350199-1

Description

RING 18-14 10 020 NIPST

Manufacturer

TE Connectivity

Type

Ring Tongue Terminalr

Datasheet

1.350199-1.pdf

(76 pages)

Specifications of 350199-1

Stud Size

10mm

Wire Gauge

14-18

Body Plating

Nickel

Body Material

Steel

Insulation

Non-Insulated

Product Depth (mm)

8.69mm

Product Length (mm)

19.89mm

Color

Not Required

Rohs Compliant

YES

Terminal Shape

Ring Tongue

Receptacle Style

Straight

Barrel Type

Open Barrel

Wire/cable Type

Regular Wire

Insulation Support

Insulation Support

Insulation Diameter (mm [in])

3.05-4.45 [.120-.175]

Stud Diameter (mm [in])

4.82 [0.190]

Shape

RING-001

Heavy Duty

No

Finish

Nickel

Wire Range (mm [awg])

0.80-2.00² [18-14]

Stock Thickness (mm [in])

0.51 [0.020]

Government/industry Qualification

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Strip

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

350199-1

Manufacturer:

TE

Quantity:

20 000

4

Catalog 82227

Revised 8-04

www.tycoelectronics.com

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

Machine Applied Terminations, Open Barrel Terminals

(Rings, Spades, Pins, Receptacles, Splices, Tabs)

Crimp Configuration Specifications

AMPLIVAR

The basic design of the

AMPLIVAR Terminals

encompasses two main

areas, the burrs at the top

of the serrations and the

serrations themselves.

During the crimping opera-

tion the burrs pierce the

insulation of the magnet

wire and extrude the bare

conductors into the serra-

tions—creating intimate

metal contact.

In a one-step operation the

magnet wire is automatically

multiple ring stripped of its

insulation as it is forced into

the serrations during the

precisely controlled crimp.

The resulting termination

produces a high tensile

strength, air sealed connec-

tion that is as resistant to

corrosion as the insulated

conductor.

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

Standard “F”

In the standard “F” crimp

design, the open barrel

consists of two wings that

are wrapped around the

conductor strands and

butted together in a tight

seam. Applied with Match-

Mated tooling, the “F” Crimp

offers the optimum combi-

nation of mechanical

strength and electrical

conductivity. This method

of termination also assures

maximum resistance to

vibration and corrosion.

The insulation support

feature was developed by

Tyco Electronics for applica-

tions where vibration tends

to be excessive. This design

offers the same fine quality

characteristics found in the

standard line plus firm, fully

circumferencial support to

the wire insulation.

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

Open Barrel

Contacts

Splices

Pins

Insulation Piercing

The insulation piercing line

enjoys a durable popularity

with electrical circuitry man-

ufacturers because of the

simplicity of attachment.

The barrel contains two per-

pendicular lances that drive

through the wire insulation

to make contact with the

conductor within.

Tensile characteristics vary,

depending on the type of

wire insulation. Because the

barrel wraps around the

insulation, it deters insula-

tion fraying. The insulation

piercing line is a low cost,

high speed attachment suit-

able for many requirements.

In general, insulation pierc-

ing terminals can be used

where high currents, inten-

sive vibration and mechani-

cal loads are not critical

factors on both stranded

and tinsel wire.

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-141-810-8967

Contacts

Pins