350199-1 TE Connectivity, 350199-1 Datasheet - Page 8

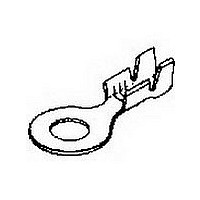

350199-1

Manufacturer Part Number

350199-1

Description

RING 18-14 10 020 NIPST

Manufacturer

TE Connectivity

Type

Ring Tongue Terminalr

Datasheet

1.350199-1.pdf

(76 pages)

Specifications of 350199-1

Stud Size

10mm

Wire Gauge

14-18

Body Plating

Nickel

Body Material

Steel

Insulation

Non-Insulated

Product Depth (mm)

8.69mm

Product Length (mm)

19.89mm

Color

Not Required

Rohs Compliant

YES

Terminal Shape

Ring Tongue

Receptacle Style

Straight

Barrel Type

Open Barrel

Wire/cable Type

Regular Wire

Insulation Support

Insulation Support

Insulation Diameter (mm [in])

3.05-4.45 [.120-.175]

Stud Diameter (mm [in])

4.82 [0.190]

Shape

RING-001

Heavy Duty

No

Finish

Nickel

Wire Range (mm [awg])

0.80-2.00² [18-14]

Stock Thickness (mm [in])

0.51 [0.020]

Government/industry Qualification

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Strip

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

350199-1

Manufacturer:

TE

Quantity:

20 000

8

Product Facts

I

I

I

I

I

I

I

I

I

Applications

I

I

I

Catalog 82227

Revised 8-04

www.tycoelectronics.com

Reproducible crimping

results

High quality

Reduced manufacturing

costs

No soldering required

Proven crimp technology

Large range of product

configurations

Excellent mechanical and

electrical performance

Appliances

Machine tools

Automotive

Recognized under the

Component Recognition

Program of

Underwriters

Laboratories Inc.,

File No. E13288, unless

otherwise specified

Certified by Canadian

Standards

Association,

File No. LR 7189, unless

otherwise specified

R

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

R

Machine Applied Terminations, Open Barrel Terminals

(Rings, Spades, Pins, Receptacles, Splices, Tabs)

Introduction

Tyco Electronics open bar-

rel rings and spades are

manufactured in strip form

and supplied on reels for

Automachine termination. In

the standard “F” crimp con-

figuration, the open barrel

consists of two “U” shaped

wings that are crimped

around the conductor

strands and butted together

into a tight seam. The

crimping action of the

Tyco Electronics application

equipment is a precise

operation that creates the

proper crimp with each

cycle of the machine. This

ensures uniformity of all the

crimp terminations.

The insulation support was a

Tyco Electronics developed

feature for applications

where vibration tends to be

excessive. The insulation

support consists of two

additional “U” shaped

wings which are wrapped

around the wire insulation.

This prevents harmful flex-

ing of the wire at the termi-

nation point where the wire

is rigidly crimped to the wire

barrel and deters fraying of

the insulation. Because it

increases the already signif-

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

icant tensile strength of

the conductor crimp, the

vibration resistance is

great enough for more

severe applications.

Tyco Electronics Open

Barrel Rings and Spades

are designed for wire sizes

ranging from 28 AWG to

6 AWG. They come in a

variety of stud sizes. These

terminals are made from a

variety of base materials

and platings depending on

your application (i.e. ambi-

ent temperature, humidity,

and chemical exposure).

To help you choose the

Tyco Electronics product

best suited to your require-

ments, the following infor-

mation about each terminal

is shown in tabular form:

wire size range, insulation

diameter, stud size, stock

thickness, type of base

material, plating and

physical dimensions.

Tyco Electronics has stan-

dardized the product listed

in this catalog section. If you

do not see a terminal to fit

your application, please con-

tact your Tyco Electronics

Sales Engineer.

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

Open Barrel Insulation

Piercing Terminals

The insulation piercing line

of terminals enjoys popular-

ity because of the simplicity

of termination. The barrel

contains two perpendicular

lances that are driven

through the wire insulation

to make contact with the

conductor. Consequently,

wire stripping is eliminated

and a one step circuitry ter-

mination is accomplished.

Tensile characteristics vary,

depending on the type of

wire insulation. Since the

barrel wraps around the

insulation, it deters insula-

tion fraying. The insulation

piercing line is a low-cost,

high-speed termination, suit-

able for many applications.

In general, insulation

piercing terminals can be

used on both stranded and

tinsel wire, where high

currents, intense vibration

and mechanical loads are

not critical factors.

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-141-810-8967