350199-1 TE Connectivity, 350199-1 Datasheet - Page 69

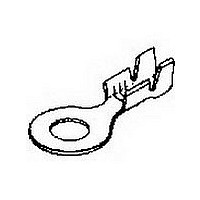

350199-1

Manufacturer Part Number

350199-1

Description

RING 18-14 10 020 NIPST

Manufacturer

TE Connectivity

Type

Ring Tongue Terminalr

Datasheet

1.350199-1.pdf

(76 pages)

Specifications of 350199-1

Stud Size

10mm

Wire Gauge

14-18

Body Plating

Nickel

Body Material

Steel

Insulation

Non-Insulated

Product Depth (mm)

8.69mm

Product Length (mm)

19.89mm

Color

Not Required

Rohs Compliant

YES

Terminal Shape

Ring Tongue

Receptacle Style

Straight

Barrel Type

Open Barrel

Wire/cable Type

Regular Wire

Insulation Support

Insulation Support

Insulation Diameter (mm [in])

3.05-4.45 [.120-.175]

Stud Diameter (mm [in])

4.82 [0.190]

Shape

RING-001

Heavy Duty

No

Finish

Nickel

Wire Range (mm [awg])

0.80-2.00² [18-14]

Stock Thickness (mm [in])

0.51 [0.020]

Government/industry Qualification

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Strip

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

350199-1

Manufacturer:

TE

Quantity:

20 000

AMP-O-LECTRIC Model G

Terminating Machines,

354500-1, -9, -11

AMP 3K/40 and AMP 5K/40

Terminating Machines

Catalog 82227

Revised 8-04

www.tycoelectronics.com

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

Machine Applied Terminations, Open Barrel Terminals

(Rings, Spades, Pins, Receptacles, Splices, Tabs)

Application Tooling

Application Tooling

The AMP 3K/40 and

AMP 5K/40 Terminators

are designed for customers

that require the increased

output and quality of a

semiautomatic machine

at a competitive price.

By incorporating the most

commonly requested fea-

tures as standard and offer-

ing a long list of optional

equipment, these termina-

tors offer flexibility to meet

the specific needs of vari-

ous applications at the low-

est possible cost.

I

3,000 lb [1361 kg] max.

crimp force (AMP 3K/40)

5,000 lb [2268 kg] max.

crimp force (AMP 5K/40)

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

(Continued)

A totally new design of

our most popular machine

for bench-top operation.

It features a quiet and

highly-reliable direct motor

drive, electronic controls

for ease of setup and oper-

ation, and improved guard-

ing and lighting for operator

convenience and safety. All

versions also include either

manual or automatic preci-

sion adjustment for crimp

height. For use with minia-

ture style applicators only.

(Shown with optional Crimp

Quality Monitor [CQM].)

I

I

I

I

I

I

Tool-less removal of

applicators and guards

Jog capability

Quiet, fast operation —

80/76 dBa and cycle time

less than 0.400 seconds

Accepts Heavy Duty Mini

style applicators

Wide range of optional

equipment such as

tool-less precision crimp

height adjust, batch

counter, CQM capability

and work light

Order Catalog 1654856 for

specs and part numbers

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

Specifications

Weight — Approximately 240 lb

[110 kg]

Width — 18.7-25.3 [475-643] depend-

ing on type of applicator used

Depth — 21.5-28.1 [546-713] depend-

ing on type of applicator used

Height — 20 [508] without reel

Electrical — 120 or 220 VAC,

50 or 60 Hz

Air — 90-110 psi [6.21-7.59 bar] when

required for use with air-feed applicators

Wire Range — 26-10 AWG

[0.12-6.0 mm

depending on product applied

For more information, request

Catalog 65828.

Specifications

Height — 20 [510] (without reel sup-

port)

Weight — Approx. 150 lb [68 kg]

Capacity —

AMP 3K/40 — 3,000 lb [1361 kg] max.

crimp force; AMP 5K/40 — 5,000 lb

[2268 kg] max. crimp force

Noise — 76 dBa maximum at 3,000 lb

[1361 kg] full capacity; 80 dBa maxi-

mum at 5,000 lb [2268 kg] full capacity

Electrical — 100-240 VAC, 50/60 Hz

(6A) • Average <1 A at 120 VAC when

used as a bench-top unit at 2 000 cycles

per hour operating rate

Air — 90-100 psi [6.21-6.90 bar],

6 scfm [0.00282 m

for use with air-feed applicators)

Note: Optional Air Feed Valve Assembly

required.

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-141-810-8967

2

] solid or stranded,

3

/s] (when required

69