350199-1 TE Connectivity, 350199-1 Datasheet - Page 46

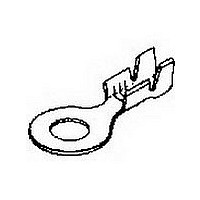

350199-1

Manufacturer Part Number

350199-1

Description

RING 18-14 10 020 NIPST

Manufacturer

TE Connectivity

Type

Ring Tongue Terminalr

Datasheet

1.350199-1.pdf

(76 pages)

Specifications of 350199-1

Stud Size

10mm

Wire Gauge

14-18

Body Plating

Nickel

Body Material

Steel

Insulation

Non-Insulated

Product Depth (mm)

8.69mm

Product Length (mm)

19.89mm

Color

Not Required

Rohs Compliant

YES

Terminal Shape

Ring Tongue

Receptacle Style

Straight

Barrel Type

Open Barrel

Wire/cable Type

Regular Wire

Insulation Support

Insulation Support

Insulation Diameter (mm [in])

3.05-4.45 [.120-.175]

Stud Diameter (mm [in])

4.82 [0.190]

Shape

RING-001

Heavy Duty

No

Finish

Nickel

Wire Range (mm [awg])

0.80-2.00² [18-14]

Stock Thickness (mm [in])

0.51 [0.020]

Government/industry Qualification

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Strip

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

350199-1

Manufacturer:

TE

Quantity:

20 000

46

9 Serrations —

Pigtail Type

Product Facts

(Plus All 7 Serration Facts)

I

I

I

I

I

I

7 Serrations —

Pigtail Type

Product Facts

I

I

I

I

I

Catalog 82227

Revised 8-04

www.tycoelectronics.com

Splice length is increased

on larger CMA splices for

improved performance

Serration depths are

varied within the splice

to give optimum electrical/

mechanical performance on

all wire sizes

Serration sidewall angles

are varied to allow better

wire stripping and

serration fill

Flat bottom of splice helps

keep magnet wires on

bottom as required during

crimping

Magnet wires 28 AWG

[0.32 mm] and larger may

be terminated without

requiring shallow serrations

Additional serrations

enhance stability of crimp

Taper on both crimper and

anvil improves flex life of

termination

Longer “flat” on tooling

improves electrical

performance (.125 vs. .080

[3.18 vs. 2.03])

Radius on wire entry end

of splice helps prevent

nicking wires and improves

mechanical performance

Serrations are offset to

sheared end to place

additional serrations in

“electrical” portion of

crimped splice

Splice CMA ranges are

overlapped so that two

splices are available for any

given CMA

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

Machine Applied Terminations, Open Barrel Terminals

(Rings, Spades, Pins, Receptacles, Splices, Tabs)

AMPLIVAR Splices

*These splices are recommended for applications using wire size 28 AWG [0.32 mm] or smaller.

1

*These splices are recommended for applications using wire size 26 AWG [0.40 mm] or smaller.

1

Special high force application equipment required.

Flat bottom.

0.26-0.80

0.38-1.54

0.38-1.54

18.5-13.5

0.80-2.54

18.5-13.5

0.80-2.54

1.54-3.46

2.54-4.90

3.46-6.38

4.90-9.45

0.38-1.54

0.38-1.54

0.38-1.54

0.38-1.54

0.38-1.54

18.5-13.5

0.80-2.54

18.5-13.5

0.80-2.54

18.5-13.5

0.80-2.54

1.54-3.46

1.54-3.46

1.54-3.46

2.10-6.38

2.10-6.0

2.10-6.0

24-18.5

22-15.5

22-15.5

15.5-12

13.5-10

22-15.5

22-15.5

22-15.5

22-15.5

15.5-12

15.5-12

15.5-12

22-15.5

10-6.5

AWG/

AWG/

12-10

12-10

mm

mm

12-9

12-9

2

2

Wire Range

Wire Range

Solid Dia.

Solid Dia.

.020-.039

0.55-1.00

.028-.055

0.70-1.40

.028-.055

0.70-1.40

.039-.071

1.00-1.80

.039-.071

1.00-1.80

.055-.083

1.40-2.10

.071-.098

1.80-2.50

.083-.112

2.10-2.85

.098-.137

2.50-3.47

.028-.055

0.70-1.40

.028-.055

0.70-1.40

.028-.055

0.70-1.40

.028-.055

0.70-1.40

0.70-1.40

.039-.071

1.00-1.80

.039-.071

1.00-1.80

.039-.071

1.00-1.80

.055-.083

1.40-2.10

1.40-2.10

.055-.083

1.40-2.10

.085-.110

2.10-2.85

2.10-2.85

.085-.115

2.10-3.47

.028-.055

.055-.083

.085-.110

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

10,000-22,000

(Continued)

Wire Range

5000-10,000

7000-13,000

Wire Range

7000-12,000

7000-12,000

7000-13,000

1500-5000

1500-5000

3000-7000

1500-5000

1500-5000

1500-5000

3000-7000

3000-7000

3000-7000

400-1500

600-3000

600-3000

600-3000

600-3000

600-3000

600-3000

600-3000

CMA

CMA

Thickness

Thickness

Stock

Stock

.016

0.41

.020

0.51

.016

0.41

.020

0.51

.016

0.41

.020

0.51

.025

0.64

.025

0.64

.030

0.76

.020

0.51

.020

0.51

.020

0.51

.020

0.51

.020

0.51

.020

0.51

.020

0.51

.020

0.51

.020

0.51

.020

0.51

.020

0.51

.025

0.64

.025

0.64

.025

0.64

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

Crimp

Width

Crimp

Width

.080

2.03

.110

2.79

.110

2.79

.110

2.79

.110

2.79

.140

3.56

.180

4.57

.180

4.57

.220

5.59

.110

2.79

.110

2.79

.110

2.79

.110

2.79

.110

2.79

.110

2.79

.110

2.79

.110

2.79

.140

3.56

.140

3.56

.140

3.56

.250

6.35

.250

6.35

.180

4.57

Dim.

Dim.

.225

5.72

.225

5.72

.225

5.72

.225

5.72

.225

5.72

.265

6.73

.265

6.73

.265

6.73

.340

8.64

.225

5.72

.225

5.72

.225

5.72

.225

5.72

.225

5.72

.225

5.72

.225

5.72

.225

5.72

.225

5.72

.225

5.72

.225

5.72

.225

5.72

.225

5.72

.225

5.72

L

L

Phosphor Bronze

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

Tin Plated Brass

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-141-810-8967

Material

Material

Brass

Brass

Brass

Brass

Brass

964156-1

62311-2

62303-2*

62304-2

62305-2*

62306-2*

62307-2*

62308-2*

62309-2*

62310-2*

Number

Number

62000-1*

62157-1*

62000-2*

62157-2*

62200-2

62040-2*

62040-1*

62001-1*

62001-2*

62201-2

62295-1*

62295-2*

62002-2*

Part

Part

1

*

1

1

*