350199-1 TE Connectivity, 350199-1 Datasheet - Page 7

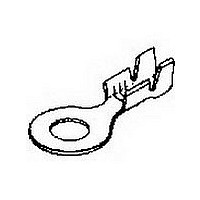

350199-1

Manufacturer Part Number

350199-1

Description

RING 18-14 10 020 NIPST

Manufacturer

TE Connectivity

Type

Ring Tongue Terminalr

Datasheet

1.350199-1.pdf

(76 pages)

Specifications of 350199-1

Stud Size

10mm

Wire Gauge

14-18

Body Plating

Nickel

Body Material

Steel

Insulation

Non-Insulated

Product Depth (mm)

8.69mm

Product Length (mm)

19.89mm

Color

Not Required

Rohs Compliant

YES

Terminal Shape

Ring Tongue

Receptacle Style

Straight

Barrel Type

Open Barrel

Wire/cable Type

Regular Wire

Insulation Support

Insulation Support

Insulation Diameter (mm [in])

3.05-4.45 [.120-.175]

Stud Diameter (mm [in])

4.82 [0.190]

Shape

RING-001

Heavy Duty

No

Finish

Nickel

Wire Range (mm [awg])

0.80-2.00² [18-14]

Stock Thickness (mm [in])

0.51 [0.020]

Government/industry Qualification

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Strip

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

350199-1

Manufacturer:

TE

Quantity:

20 000

Wire Size Range

AWG 22 to 2

Test Sequences

Test Group 1

Mechanical Sequence

1. Secureness

2. Pullout

Test Group 2

Mechanical Sequence

1. Secureness

2. Static Heat

3. Pullout

Catalog 82227

Revised 8-04

www.tycoelectronics.com

Test Terminal

Bushing

Weight

(From Bushing

Arm rotates

in a circular motion

on the horizontal

plane at 9 RPM.

Circular motion

has a diameter

of 3 inches.

To Wire)

Stationary

Mounting

Fixture

Height

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

Machine Applied Terminations, Open Barrel Terminals

(Rings, Spades, Pins, Receptacles, Splices, Tabs)

Description of UL 486A Test Procedures and Requirements for Terminals

Terminal must not be separate from wire when

subjected to the listed load for one minute.

Note: Testing conducted on non-plated

copper wire with UL approved insulation.

Secureness Test Requirements

Note: Test Duration = 30 Minutes

Pullout Test Requirements

Wire Size

Wire Size

18 -16

12 -10

AWG

AWG

22

20

18

16

14

12

10

14

8

6

4

2

8

6

4

2

Bushing

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

Dia.

9/16

1/4

3/8

3/8

3/8

1/2

1/2

Force (lbs.)

Pullout

100

140

180

13

20

30

50

70

80

90

8

Height

10 1/4

11 3/4

11 3/4

12 1/2

11

11

11

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

Weight

(lbs.)

18

30

30

2

3

5

8

Requirement:

Connector temperatures must not exceed the ambi-

ent temperature plus 50°C [90°F] after stability is

attained.

Stability:

A test sample is considered to have attained a stable

temperature when three readings taken at not less

than 10 minute intervals show no more than a 2°C

[3.6°F] variation between any two readings.

Static Heat Test Requirements

Wire Size

AWG

22

20

18

16

14

12

10

8

6

4

2

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-141-810-8967

Test Current

(Amperes)

125

170

12

17

18

30

35

50

70

95

9

7