350199-1 TE Connectivity, 350199-1 Datasheet - Page 40

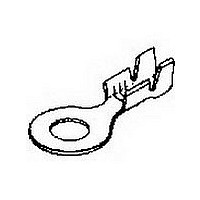

350199-1

Manufacturer Part Number

350199-1

Description

RING 18-14 10 020 NIPST

Manufacturer

TE Connectivity

Type

Ring Tongue Terminalr

Datasheet

1.350199-1.pdf

(76 pages)

Specifications of 350199-1

Stud Size

10mm

Wire Gauge

14-18

Body Plating

Nickel

Body Material

Steel

Insulation

Non-Insulated

Product Depth (mm)

8.69mm

Product Length (mm)

19.89mm

Color

Not Required

Rohs Compliant

YES

Terminal Shape

Ring Tongue

Receptacle Style

Straight

Barrel Type

Open Barrel

Wire/cable Type

Regular Wire

Insulation Support

Insulation Support

Insulation Diameter (mm [in])

3.05-4.45 [.120-.175]

Stud Diameter (mm [in])

4.82 [0.190]

Shape

RING-001

Heavy Duty

No

Finish

Nickel

Wire Range (mm [awg])

0.80-2.00² [18-14]

Stock Thickness (mm [in])

0.51 [0.020]

Government/industry Qualification

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Strip

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

350199-1

Manufacturer:

TE

Quantity:

20 000

40

MTM Crimpband

Interconnection System

How the System Operates

➀

➁

➂

➃

➄

Connector Specification Code

Splice No.

Example:

Legend

* Customer has their own Tooling

Catalog 82227

Revised 8-04

www.tycoelectronics.com

Leased

Machine

Feed (Magnet Wire

Connector Material)

Machine feeds strip until

the strip hits the wire stop.

Shear (Blank Length)

The strip is cut by the

cutter block former bar

insert tooling.

Bend (Crimp Formed)

The former bar drives the

cut strip over the anvil,

bending the cut strip into

an upside down “U”.

Wire (Placement)

In Pigtail and Parallel

(Thru) splices magnet

wires must be placed on

top of the lead wire.

Crimp (Crimp Formed)

The anvil retracts as the

driver takes the formed

strip down into the

clincher.

Basis

L

L

Machine Basis

Purchase

B.L. Dim.

Tooling

L

Size

P

092

092

See Figure 1 and/or Legend below

General

Connector

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

W Dim.

G*

Width

6R

6R

Machine Applied Terminations, Open Barrel Terminals

(Rings, Spades, Pins, Receptacles, Splices, Tabs)

MTM Crimpband Splices

Note: For B/L above, .546 consult

Tyco Electronics for tooling size

code.

Thickness

Material

T Dim.

20

Size Code

Tooling

032/036

061/076

076/092

092/125

125/160

125/165

20

032

036

045

051

061

076

092

125

165

T

Finish

T

Blank Length

B/L (Nom.)

B

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

.167

.228

.224

.246

.267

.292

.324

.339

.361

.379

.413

.446

.485

.506

.546

Material

Code

B

A

(Continued)

Notes: So that the proper Crimpband splice is chosen, Tyco Electronics

Thickness

Connector Width Code

Material

Material

10R

4R

6R

8R

Code

Code

TB

12

14

16

20

25

B

A

recommends the following:

1. Submit 10 samples of wire combinations and/or components to be

2. Pull-out force and/or millivolt drop tests will be performed to

3. Tooling and testing will be documented on a Material & Tooling

4. Crimpband material quotes, tooling quotes and samples will be

➀

Magnet Wires

on top

crimped with any special requirements to your Tyco Electronics

sales representative.

develop recommendations for proper Crimpband material, toolset

and crimp heights.

Sheet (M & T sheet).

submitted to the customer.

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

A

11 Serrations

Lead Wire

5 Serrations

7 Serrations

9 Serrations

CDA 725 Copper/

T±.002

Material/Finish

CDA 260 Brass

CDA 260 Brass

Dim.

.012

.014

.016

.020

.025

Pre-Tin over

Nickel Alloy

Serration

➄

Depth

➂

T

.005

.005

.007

.007

.007

➃

➁

D

.138

.154

.194

.234

W

Burrs

Section A-A

Wire Size Force Requirements

Length

AWG

Blank

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-141-810-8967

W

26

24

22

20

18

16

14

12

10

W

Serrations

UL486C Pull Out

Laboratory (lbs.)

Underwriters

10

10

15

25

35

40

3

5

8

D