XR17C158CV-F Exar Corporation, XR17C158CV-F Datasheet - Page 32

XR17C158CV-F

Manufacturer Part Number

XR17C158CV-F

Description

IC UART PCI BUS 5V OCTAL 144LQFP

Manufacturer

Exar Corporation

Type

Universal PCI Bus Octal UARTr

Datasheet

1.XR17C158CV-F.pdf

(67 pages)

Specifications of XR17C158CV-F

Number Of Channels

8

Package / Case

144-LQFP

Features

*

Fifo's

64 Byte

Protocol

RS485

Voltage - Supply

5V

With Auto Flow Control

Yes

With Irda Encoder/decoder

Yes

With False Start Bit Detection

Yes

With Modem Control

Yes

Mounting Type

Surface Mount

Data Rate

6.25 Mbps

Supply Voltage (max)

7 V

Supply Current

5 mA

Maximum Operating Temperature

+ 85 C

Minimum Operating Temperature

- 40 C

Mounting Style

SMD/SMT

Operating Supply Voltage

7 V

No. Of Channels

8

Uart Features

High Performance, Read/Write Burst Operation

Supply Voltage Range

-0.5V To 7V

Operating Temperature Range

0°C To +70°C

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

1016-1287

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

XR17C158CV-F

Manufacturer:

Exar Corporation

Quantity:

10 000

Part Number:

XR17C158CV-F

Manufacturer:

EXAR/艾科嘉

Quantity:

20 000

XR17C158

5V PCI BUS OCTAL UART

Automatic hardware RTS/CTS or DTR/DSR flow control is used to prevent data overrun to the local receiver

FIFO and remote receiver FIFO. The RTS#/DTR# output pin is used to request the remote unit to suspend/

restart data transmission while the CTS#/DSR# input pin is monitored to suspend/restart the local transmitter.

The auto RTS/CTS or DTR/DSR flow control features are individually selected to fit specific application

requirement and enabled through EFR bit-6 and 7 and MCR bit-2 for either RTS/CTS or DTR/DSR control

signals.

Auto RTS flow control must be started by asserting the RTS# output pin LOW (MCR bit-1 = 1). Similarly, Auto

DTR flow control must be started by asserting the DTR# output pin LOW (MCR bit-0 = 1).

detail how automatic hardware flow control works.

Two interrupts associated with auto RTS/CTS and DTR/DSR flow control have been added to give indication

when RTS#/DTR# pin or CTS#/DSR# pin are de-asserted during operation. These interrupts are enabled by:

•

•

•

Automatic hardware flow control is selected by setting bits 6 (RTS) and 7 (CTS) of the EFR register to logic 1.

If CTS# pin transitions from LOW to HIGH indicating a flow control request, ISR bit-5 will be set to logic 1, (if

enabled via IER bit 6-7), and the UART will suspend TX transmissions as soon as the stop bit of the character

in process is shifted out. Transmission is resumed after the CTS# input returns LOW, indicating more data may

be sent.

4.4

Setting EFR bit-4 =1 to enable the shaded register bits

Setting IER bit-7 will enable the CTS#/DSR# interrupt when these pins are de-asserted. The selection of

CTS# or DSR# is selected via MCR bit-2. See

Setting IER bit-6 will enable the RTS#/DTR# interrupt when these pins are de-asserted. The selection of

RTS# or DTR# is selected via MCR bit-2. See

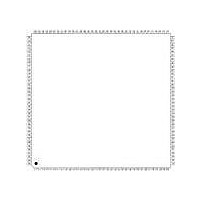

MCR B

Automatic Hardware (RTS/CTS or DTR/DSR) Flow Control Operation

X

0

0

1

1

IT

-2

T

ABLE

10: A

EFR B

UTO

1

X

1

X

0

IT

-7

RTS/CTS

OR

Table 10

Table 10

DTR/DSR F

EFR B

32

X

X

1

1

0

IT

above for complete details.

above for complete details.

-6

LOW

C

ONTROL

Auto DSR Flow Control Enabled

Auto DTR Flow Control Enabled

Auto CTS Flow Control Enabled

Auto RTS Flow Control Enabled

F

LOW

S

ELECTION

No Flow Control

C

ONTROL

Figure 14

S

ELECTION

xr

REV. 1.4.3

shows in