QDE-825D BANNER ENGINEERING, QDE-825D Datasheet - Page 2

QDE-825D

Manufacturer Part Number

QDE-825D

Description

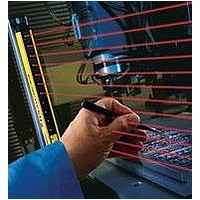

Safety Light Curtain

Manufacturer

BANNER ENGINEERING

Datasheet

1.QDE-815D.pdf

(74 pages)

Specifications of QDE-825D

Light Curtain Type

Safety

Accessory Type

Machine Interface Cable

For Use With

EZ-Screen Safety Light Screen

1. System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

2. System Components and Specifications . . . . . . . . . . . . . . . . . Page 6

3. Installation and Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 21

4. System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 41

5. Troubleshooting and Maintenance. . . . . . . . . . . . . . . . . . . . . . Page 47

6. Checkout Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 52

7. Cascadeable EZ-SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 54

Glossary of Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 65

Safety Standards and Regulations . . . . . . . . . . . . . . . . Inside Back Cover

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Applications and Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Control Reliability: Redundancy and Self-Checking. . . . . . . . . . . . . . . 2

1.4 Operating Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Emitter and Receiver Models – 14 mm . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Emitter and Receiver Models – 30 mm . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6 Literature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.7 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Mechanical Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 Mechanical Mounting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3 Initial Electrical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.4 Light Screen Initial Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.5 Electrical Interface to the Guarded Machine (Permanent

3.6 Preparing for System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.7 Sensor “Swapability” and the Optional Emitter Hookup . . . . . . . . . . . .38

4.1 Security Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.2 System Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.3 Reset Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.4 Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.5 Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.6 Periodic Checkout Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.1 Troubleshooting Lockout Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2 Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.3 Electrical and Optical Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.4 Servicing and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.1 Schedule of Checkouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.2 Commissioning Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.3 Shift/Daily Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.4 Semi-Annual (Six-Month) Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.1 Overview of Cascading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.2 Cascadeable Emitter and Receiver Models – 14 mm . . . . . . . . . . . . 55

7.3 Cascadeable Emitter and Receiver Models – 30 mm . . . . . . . . . . . . 56

7.4 Determining Interconnect Cable Lengths . . . . . . . . . . . . . . . . . . . . . . 57

7.5 Response Time for Cascaded Light Screens . . . . . . . . . . . . . . . . . . . 59

7.6 Cascaded Sensor Configuration Settings. . . . . . . . . . . . . . . . . . . . . . 61

7.7 Programming for Cascaded Operation. . . . . . . . . . . . . . . . . . . . . . . . 61

7.8 E-Stop Buttons and Rope/Cable Pulls . . . . . . . . . . . . . . . . . . . . . . . . 62

7.9 Positive-Opening Safety Interlock Switches . . . . . . . . . . . . . . . . . . . . .63

Table of Contents

Hookup) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Important

read this page before proceeding!

In the United States, the functions that EZ-SCREEN is intended

to perform are regulated by the Occupational Safety and Health

Administration (OSHA). Outside of the United States, these

functions are regulated by other agencies, organizations, and

governments. Whether or not any particular EZ-SCREEN

installation meets all applicable requirements depends upon

factors that are beyond the control of Banner Engineering Corp.

These factors include the details of how the EZ-SCREEN is

applied, installed, wired, operated, and maintained. It is the

responsibility of the purchaser and user to apply this

EZ-SCREEN System in full compliance with all relevant

applicable regulations and standards.

EZ-SCREEN can guard against accidents only when it is

properly installed and integrated into the machine, properly

operated, and properly maintained. Banner Engineering Corp.

has attempted to provide complete application, installation,

operation, and maintenance instructions. In addition, please

direct any questions regarding application or use of EZ-SCREEN

to the factory applications department at the telephone number

or addresses shown on the back cover.

In addition to OSHA regulations, several other organizations

provide information about the use of safeguarding devices.

Refer to the American National Standards Institute (ANSI),

the Robotics Industries Association (RIA), the Association for

Manufacturing Technology (AMT), and others (see below).

Banner Engineering Corp. makes no claim regarding a

specific recommendation of any organization, the accuracy or

effectiveness of any information provided, or the appropriateness

of the provided information for a specific application.

The user has the responsibility to ensure that all local, state,

and national laws, rules, codes, and regulations relating

to the use of this safeguarding system in any particular

application are satisfied. Extreme care is urged to ensure

that all legal requirements have been met and that all

installation and maintenance instructions contained in this

manual are followed.

OSHA 29CFR1910 Occupational Safety and Health Standards

ANSI/RIA R15.06 Safety Requirements for Robot Systems

ap pli ca ble U.S., European and International stan dards,

NFPA 79 Electrical Standard for Industrial Machinery

See inside back cover for information pertaining to

ANSI B11 Standards Safeguarding of Machine Tools

U.S. Standards Applicable to Use of EZ-SCREEN

and where to acquire copies.

...

Banner Engineering Corp.

www.bannerengineering.com • Tel: 763.544.3164

Instruction Manual

•

Minneapolis, U.S.A.

EZ-SCREEN