QDE-825D BANNER ENGINEERING, QDE-825D Datasheet - Page 68

QDE-825D

Manufacturer Part Number

QDE-825D

Description

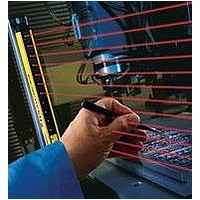

Safety Light Curtain

Manufacturer

BANNER ENGINEERING

Datasheet

1.QDE-815D.pdf

(74 pages)

Specifications of QDE-825D

Light Curtain Type

Safety

Accessory Type

Machine Interface Cable

For Use With

EZ-Screen Safety Light Screen

66

66

Fixed Blanking: A programming feature that allows a safety light

screen system to ignore objects (such as brackets or fixtures)

which will always be present at a specific location within the

defined area. The presence of these objects will not cause the

system’s safety outputs (e.g., Final Switching Devices) to trip or

latch. If any fixed objects are moved within or removed from the

defined area, a Lockout condition results.

Floating Blanking: See Reduced Resolution.

FMEA (Failure Mode and Effects Analysis): A testing

procedure by which potential failure modes in a system are

analyzed to determine their results or effects on the system.

Component failure modes that produce either no effect or a

Lockout condition are permitted; failures which cause an unsafe

condition (a failure to danger) are not. Banner safety products

are extensively FMEA tested.

Guarded Machine: The machine whose point of operation is

guarded by the safety system.

Hard Guard: Screens, bars, or other mechanical barriers

affixed to the frame of the machine intended to prevent entry

by personnel into the hazardous area(s) of a machine, while

allowing the point of operation to be viewed. The maximum size

of openings is determined by the applicable standard, such as

Table O-10 of OSHA 29CFR1910.217, also called a “fixed barrier

guard.”

Hazardous Area: An area that poses an immediate or impending

physical hazard.

Hazard Point: The closest reachable point of the hazardous

area.

Internal Lockout: A Lockout condition that is due to an internal

safety system problem. Generally, indicated by the red Status

indicator LED (only) flashing. Requires the attention of a

Qualified Person.

Key Reset (Manual Reset): A key-operated switch used to reset

a safety light screen system to RUN mode following a Lockout

condition, or to enable machine operation following a Latch

condition. Also refers to the act of using the switch.

Latch Condition: The response of the safety light screen Safety

Outputs (e.g., OSSDs) when an object equal to or greater than

the diameter of the specified test piece enters the defined area.

In a Latch condition, safety outputs simultaneously de-energize

and open their contacts. The contacts are held (latched) open

until the object is removed from the defined area and a manual

reset is performed. A latching output is used most often in

perimeter guarding applications. (See Trip Condition.)

Lockout Condition: A safety light screen condition that is

automatically attained in response to certain failure signals (an

internal lockout). When a Lockout condition occurs, the safety

light screen’s safety outputs turn OFF; the failure must be

corrected and a manual reset is required to return the system to

RUN mode.

P/N 133487

P/N 112852 rev. F

Overview

Glossary

Machine Primary Control Element (MPCE): An electrically

powered element, external to the safety system, which directly

controls the machine’s normal operating motion in such a way

that the element is last (in time) to operate when machine

motion is either initiated or arrested.

Machine Response Time: The time between the activation of

a machine stopping device and the instant when the dangerous

parts of the machine reach a safe state (are brought to rest).

Minimum Object Sensitivity (MOS): The minimum-diameter

object that a safety light screen system can reliably detect.

Objects of this diameter or greater will be detected anywhere in

the defined area. A smaller object can pass undetected through

the light if it passes exactly midway between two adjacent light

beams. Also known as MODS (Minimum Object Detection Size).

See also Specified Test Piece.

Muting: The automatic suspension of the safeguarding function

of a safety device during a non-hazardous portion of the

machine cycle.

OFF State: The state in which the output circuit is interrupted

and does not permit the flow of current.

ON State: The state in which the output circuit is complete and

permits the flow of current.

OSHA (Occupational Safety and Health Administration): A

U.S. Federal agency, Division of the U.S. Department of Labor,

that is responsible for the regulation of workplace safety.

OSSD: Output Signal Switching Device. The safety outputs that

are used to initiate a stop signal.

Part-Revolution Clutch: A type of clutch that may be engaged

or disengaged during the machine cycle. Part-revolution

clutched machines use a clutch/brake mechanism, which can

arrest machine motion at any point in the stroke or cycle.

Pass-Through Hazard: A situation that may exist when

personnel pass through a safeguard (at which point the hazard

stops or is removed), and then continue into the guarded area.

At this point the safeguard may not be able to prevent an

unexpected start or restart of the machine with personnel within

the guarded area.

Point of Operation: The location of a machine where material

or a workpiece is positioned and a machine function is

performed upon it.

Banner Engineering Corp.

Banner Engineering Corp.

www.bannerengineering.com • Tel: 763.544.3164

www.bannerengineering.com • Tel: 763.544.3164

Instruction Manual

•

•

Minneapolis, U.S.A.

Minneapolis, U.S.A.

EZ-SCREEN