QDE-825D BANNER ENGINEERING, QDE-825D Datasheet - Page 31

QDE-825D

Manufacturer Part Number

QDE-825D

Description

Safety Light Curtain

Manufacturer

BANNER ENGINEERING

Datasheet

1.QDE-815D.pdf

(74 pages)

Specifications of QDE-825D

Light Curtain Type

Safety

Accessory Type

Machine Interface Cable

For Use With

EZ-Screen Safety Light Screen

EZ-SCREEN

Instruction Manual

Mount the reset switch in a location that complies with the warning

in Section 3.1.3. See Section 3.3.2 for electrical connection.

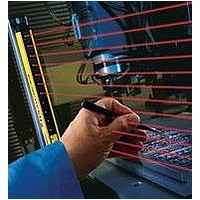

Connect the QD connectors and route the sensor cables to the

junction box, electrical panel, or other enclosure in which the

Interface Module, the redundant mechanically linked interposing

relays, FSDs, or other safety-related parts of the control system

are located. This must be done per local wiring code for low-

voltage dc control cables and may require installation of electrical

conduit. See Section 2.2 for selection of Banner-supplied cables.

EZ-SCREEN is designed and manufactured to be highly

resistant to electrical noise and to operate reliably in industrial

settings. However, extreme electrical noise may cause a random

Trip or Latch condition; in extreme cases, a Lockout is possible.

Emitter and receiver wiring is low voltage; routing the sensor

wires alongside power wires, motor/servo wires, or other high-

voltage wiring may inject noise into the EZ-SCREEN System.

It is good wiring practice (and may be required by code) to

isolate emitter and receiver cables from high-voltage wires,

avoid routing cables close to “noisy” wiring, and provide a good

connection to earth ground.

Sensor QD cabling and any interconnect wiring should meet

the following specifications. The wires used should have an

insulation temperature rating of at least 90°C (194°F).

* QDE-...D cables, see table 2.2

NOTE: Maximum cable lengths are intended to ensure that

See Section 7.4 for cascade installations.

3.2.2 Mounting the Reset Switch

3.2.3 Routing Cables

Electrical hookup must be made by Qualified Personnel

and must comply with NEC (National Electrical Code) and local

standards.

Make no more connections to the EZ-SCREEN System than are

described in Sections 3.3.1 through 3.5.3 of this manual.

Connection of other wiring or equipment to the EZ-SCREEN

System could result in serious bodily injury or death.

22 AWG*

Banner Engineering Corp.

Banner Engineering Corp.

18 AWG

20 AWG

www.bannerengineering.com • Tel: 763.544.3164

www.bannerengineering.com • Tel: 763.544.3164

WARNING . . .

adequate power is available to the EZ-SCREEN System

when the supply is operating at +24V dc – 15%.

versus total current draw (including both OSSD loads)

Maximum Machine Interface cable length (ft)

0.5A

375

240

150

0.75A

250

160

100

•

•

Minneapolis, U.S.A.

Minneapolis, U.S.A.

Proper Electrical Hookup

1.0A

188

120

75

1.25A

148

95

59

1.5A

125

80

50

1.75A

109

70

44

Lockout/tagout procedures may be required (refer to OSHA

29CFR1910.147, ANSI Z244-1, or the appropriate standard

for controlling hazardous energy). Following relevant electrical

standards and wiring codes, such as the NEC, NFPA79 or

IEC60204-1, always connect earth ground (green/yellow

wire, see Figures 3-20 through 3-23). Do not operate the

EZ-SCREEN System without an earth ground connection.

See the warning below.

Make the electrical connections in the order described in this

section. Do not remove end-caps; no internal connections are to

be made. All connections are made through the M12 Euro-style

quick-disconnects.

When installing QD cables, do not use tools to tighten the

coupling nut (i.e. hand-tighten only). Do not rotate the body of

the QD, or damage to the connector can occur.

Emitter Cable

Standard EZ-SCREEN emitters have an 8-pin cable, but only

three conductors are used (Brown = +24V dc, Blue = 0V dc,

Green/Yellow = GND). The other wires are in place to allow a

parallel connection (color-for-color) to the receiver cable (see

Figure 3-19), providing sensor interchangeability (or swapability);

either sensor may be installed at either cordset connection.

In addition to providing similar cabling, this wiring scheme is

advantageous during installation, wiring, and troubleshooting.

Emitters with the optional TEST function (model number suffix

Q5) use a 5-pin cable (see Figure 3-20). Locate the black and

the white wires at the cable end; if the Test input will be used,

temporarily connect the ends of the wires to each other (but not

to an external contact at this time). If the Test input will not

be used, connect the emitter cable black and white wires

together and properly terminate (e.g., with the included

wire-nut).

Receiver Cable

Do not connect any wires to the machine control circuits

(i.e., OSSD outputs) at this time. For the initial power-up and

checkout, NO EDM must be configured. Locate the orange and

orange/black wires (pins 2 and 3) and temporarily connect the

ends of the wires to each other (but not to the machine at this

time). Take precautions to prevent the wires from shorting to

ground or to other sources of energy (e.g., terminate with the

included wire-nut). Final EDM wiring must be completed later.

If used, connect the external reset switch to the reset wire

(violet) on the receiver cable and to 24V dc (see Figures 3-21

and 3-23). See warning in Section 3.1.3 about the physical

location of the external reset switch. The reset switch must be

a normally open switch that is held closed for approximately 1/4

second, but no longer than 2 seconds, and then re-opened to

accomplish the reset. The switch must be capable of switching

10 to 30V dc at 30 mA.

3.3 Initial Electrical Connections

Installation and Alignment

Overview

P/N 112852 rev. F

P/N 133487

29

29