SP400-0.009-00-11 Bergquist, SP400-0.009-00-11 Datasheet - Page 18

SP400-0.009-00-11

Manufacturer Part Number

SP400-0.009-00-11

Description

THERMAL PAD TO-3 .009" SP400

Manufacturer

Bergquist

Series

Sil-Pad® 400r

Specifications of SP400-0.009-00-11

Usage

TO-3, TO-66

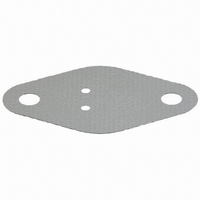

Shape

Rhombus

Outline

33.32mm x 19.35mm

Thickness

0.009" (0.229mm)

Backing, Carrier

Fiberglass

Color

Gray

Thermal Resistivity

1.40°C/W

Thermal Conductivity

0.9 W/m-K

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Adhesive

-

Other names

7403-09FR-11

BER218

BER218

16

Electrical Design Considerations

t

t

t

Proof Test

The purpose of "Proof Testing" Thermal Clad substrates is to verify

that no defects reside in the dielectric material. Because testing

requires that voltages be above the onset of partial discharge, we rec-

ommend the number of “Proof Tests” be kept at a minimum.

The term "Partial Discharge" includes a broad spectrum of life

reducing (i.e. material damaging) phenomena such as:

1.

2.

3.

4.

“Proof Test” fixture to test multiple number of finished circuit boards at one time.

Proof Testing

Breakdown Voltage

Creepage Distance And Discharge

Corona discharge

Treeing and surface contamination

Surface discharges at interfaces, particularly during fault

induced voltage reversal

Internal discharges in voids or cavities within the dielectric

Breakdown Voltage

The ASTM definition of dielectric breakdown voltage is: the potential

difference at which dielectric failure occurs under prescribed condi-

tions in an electrical insulating material located between two elec-

trodes. This is permanent breakdown and is not recoverable. ASTM

goes on to state that the results obtained by this test can seldom be

used directly to determine the dielectric behavior of a material in an

actual application. This is not a test for “fit for use” in the application,

as is the “Proof Test” , which is used for detection of fabrication and

material defects to the dielectric insulation.

The purpose of the “Proof Test” is to verify that there has been no

degradation of the dielectric insulation due to the fabrication process

or any material defects. Continued testing at these voltage levels will

only take away from the life of the dielectric on the circuit board. It

has been repeatedly verified that “Proof Testing” above the inception

of partial discharge (700 Vac or 1200 Vac with proper use of solder-

mask) will detect any and all defects in the dielectric isolation in the

Thermal Clad circuit board. Any micro-fractures, delaminations or

micro-voids in the dielectric will breakdown or respond as a short

during the test.

The use of a DC “Proof Test” is recommended, from an operator

safety standpoint. The voltage levels typically used are 1500 to 2250

VDC. Due to the capacitive nature of the circuit board construction,

it is necessary to control the ramp up of the voltage to avoid nui-

sance tripping of the failure detect circuits in the tester and to main-

tain effective control of the test. This is to avoid premature surface

arcing or voltage overshoot. There is safety consideration when DC

testing, in that the operator must verify the board tested is fully dis-

charged, prior to removing from the test fixture. A more detailed dis-

cussion of “Proof Test” is available upon request.